Across Canada, precast concrete has become a preferred choice for developers, contractors, and architects who need fast, reliable, and cost-effective building solutions. From large commercial buildings to residential complexes and industrial structures, precast concrete elements allow teams to build stronger, faster, and with far greater efficiency than traditional cast-in-place methods. Yet many industry professionals still wonder: Which types of precast elements are available? What are their differences? And which ones are right for my project? There are many types of precast concrete used across Canadian construction, each serving different structural and architectural purposes.

This in-depth guide breaks down the most common types of precast concrete elements—including walls, slabs, beams, columns, stairs, and specialty components—helping you understand their functions, advantages, and real-world applications. With insights rooted in engineering best practices, Canadian building standards, and professional experience from Omega Precast, this article helps you choose the right precast solutions with confidence.

What Are Precast Concrete Elements?

Precast concrete elements are building components manufactured in a controlled facility before being transported to a construction site for installation. Instead of pouring concrete on-site—where weather, temperature, and labor availability may affect quality—precast is produced using precise molds, specialized curing systems, and strict quality controls.

This manufacturing method ensures consistent strength, predictable performance, and faster project timelines. Understanding the different types of precast concrete helps builders choose the right elements for long-term durability and efficiency. According to the Cement Association of Canada, precast systems can reduce construction schedules by up to 30–50% compared to cast-in-place methods.

Precast vs. Cast-In-Place: Key Differences

- Quality Control: Precast is produced in a factory; cast-in-place depends heavily on site conditions.

- Speed: Precast arrives ready to install; cast-in-place requires formwork, curing time, and more labor.

- Durability: Precast cures under optimal conditions; cast-in-place is exposed to variable weather.

- Consistency: Precast elements have uniform strength and finish; cast-in-place varies by job site quality.

For large-scale projects across Canada—where weather can cause delays and structural standards are strict—precast offers a dependable and high-performance alternative. Among all types of precast concrete, wall panels and hollow-core slabs remain the most widely used in Canadian commercial and industrial projects.

Benefits of Using Precast Concrete in Construction

Different types of precast concrete offer unique advantages depending on project demands, load requirements, and environmental conditions. Precast concrete is used worldwide, but it has become especially valuable in Canada’s construction environment, where developers face deadlines, labor shortages, and long winter seasons. Here are the key benefits.

Faster Installation & Lower Labour Costs

Because precast elements arrive ready to install, on-site labor requirements decrease significantly. Crews can complete building structures in days instead of weeks. This efficiency is crucial for projects in areas with limited labor availability.

Higher Quality Through Controlled Manufacturing

Precast is produced under factory-controlled conditions using calibrated machinery and standardized curing processes. This results in:

- consistent compressive strength

- superior surface finish

- improved dimensional accuracy

- fewer defects and onsite rework

When comparing various types of precast concrete, engineers often focus on accuracy, finish quality, and long-term structural behaviour.

Improved Durability & Structural Performance

Precast concrete is exceptionally strong and resistant to moisture, temperature fluctuations, and heavy loads. It performs well in Canada’s freeze-thaw environment and has a lifespan that often exceeds 75–100 years.

Greater Design Flexibility for Architects

Modern precast manufacturing can produce custom shapes, textures, finishes, and integrated insulation systems. Designers can achieve both structural function and architectural appeal without compromise.

Better Weather Resistance for Canadian Climates

From coastal moisture in British Columbia to freezing temperatures in Alberta and Ontario, precast concrete resists the harshest environmental conditions with minimal maintenance needs.

Main Types of Precast Concrete Elements

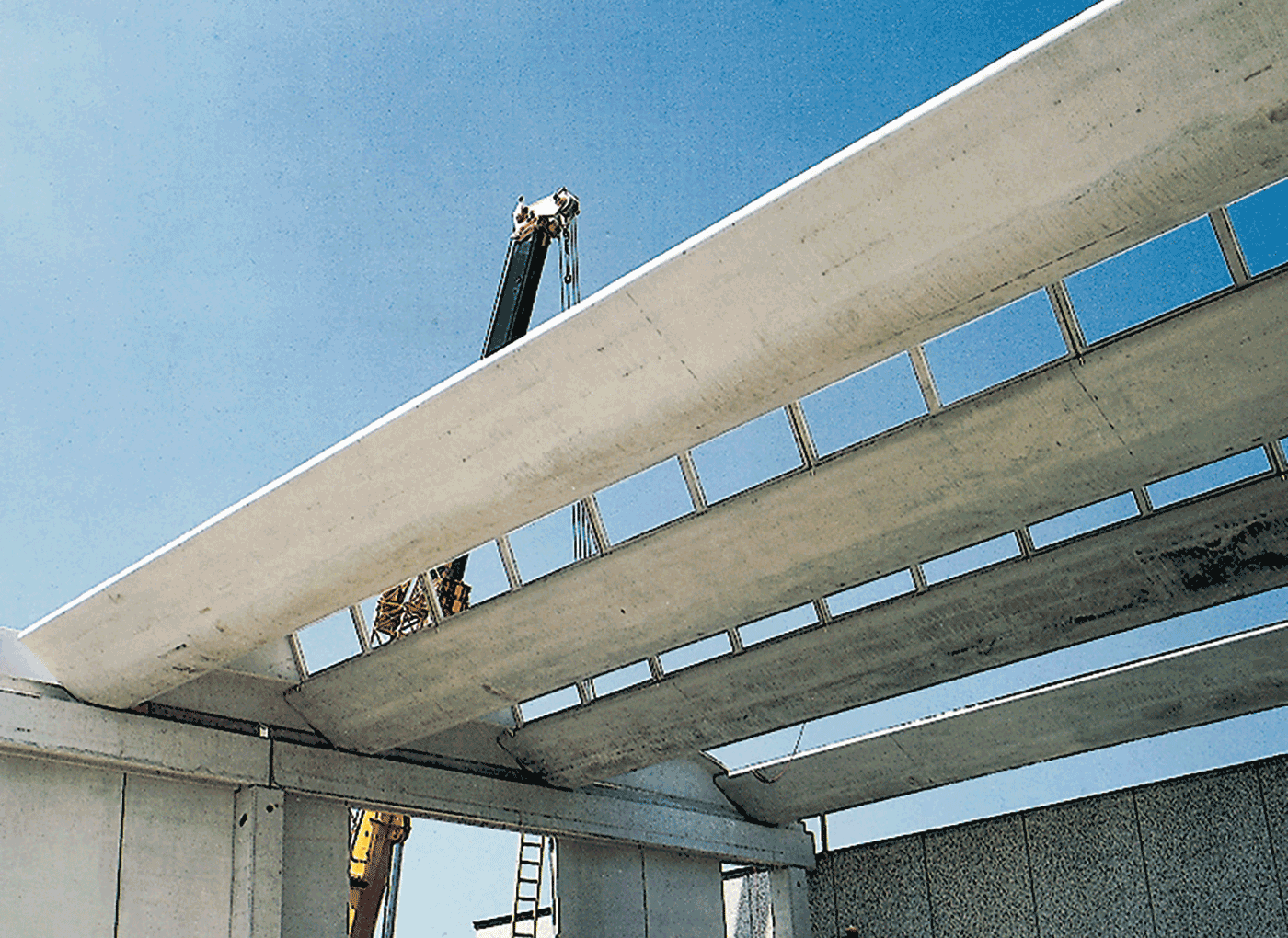

Modern manufacturing allows all types of precast concrete to be produced with precise dimensions and high-quality consistency.

The heart of precast construction lies in the variety of elements available. Below are the core precast components most commonly used in Canadian commercial, industrial, and residential projects.

1. Precast Concrete Walls

Precast concrete walls are among the most widely used components in construction. They offer excellent strength, thermal performance, and quick installation—making them ideal for large buildings, warehouses, data centers, and multi-residential projects.

Load-Bearing Walls

These walls support vertical loads from floors and roofs. They are engineered to handle significant structural demands and are commonly used in industrial facilities and multi-story buildings.

Non-Load-Bearing Walls

These walls act as exterior enclosures or interior partitions. They provide aesthetic appeal, thermal insulation, and sound control without carrying structural loads.

Insulated Sandwich Panels

Popular in cold Canadian climates, insulated panels combine:

- outer concrete layer

- rigid foam insulation core

- inner concrete layer

This design improves energy efficiency and reduces heating costs, making it a top choice for commercial and industrial projects.

Architectural Wall Panels

Architectural precast offers a wide spectrum of surface finishes, colors, and custom patterns. Designers use them to achieve visually appealing exteriors without sacrificing durability. Some types of precast concrete are specifically designed for architectural use, offering a broad range of textures, colours, and creative design options.

Applications

- Commercial façades

- Schools and hospitals

- Industrial buildings

- Residential mid-rise construction

Advantages

- Long service life

- Rapid installation

- Superior fire resistance

- Excellent thermal performance

Across industrial and commercial projects, the most common types of precast concrete include wall panels, insulated sandwich panels, and architectural façade systems.

2. Precast Concrete Slabs

Precast slabs are horizontal structural components designed to support floors and roofs. They are extremely efficient for large spans and heavy loads, making them a common choice for commercial complexes, warehouses, parking structures, and schools.

Hollow-Core Slabs

Engineered with continuous voids to reduce weight while maintaining strength. They offer excellent span capabilities—often up to 12–18 meters—and improve installation speed dramatically.

Solid Slabs

Used when additional fire resistance or acoustic control is required. These slabs are durable, versatile, and suitable for mechanical room floors and areas with heavy loads.

Double-T Slabs

Double-T (TT) slabs combine the benefits of precast slabs and beams. Their shape provides exceptional load capacity and long spans, making them ideal for parking garages and industrial buildings.

Best Use Cases

- Commercial flooring systems

- Underground parking structures

- School and hospital floors

- Industrial warehouses

3. Precast Concrete Beams

Precast beams support floor slabs, roof structures, and large spans between columns. They are designed to carry significant loads and are produced in a variety of profiles to meet project specifications.

Rectangular Beams

Simple, versatile, and commonly used for smaller buildings or where architectural finishes are required.

L-Beams

Designed to support flooring systems such as hollow-core slabs. They help create integrated structural frameworks with minimal on-site work.

Inverted-T Beams

These beams offer extended ledges for supporting slabs and allow for long, uninterrupted spans—ideal for open interior layouts.

Structural Functions & Support Systems

- Transfers loads from floors to columns

- Reduces the need for temporary shoring

- Allows faster multi-storey construction

- Improves building rigidity and seismic performance

Structural types of precast concrete are engineered to withstand heavy loads, seismic activity, and Canada’s harsh climate conditions.

4. Precast Concrete Columns

Precast concrete columns play a vital role in transferring loads safely from beams and slabs to the foundation. Their precision, strength, and speed of installation make them a preferred choice for multi-story buildings, industrial facilities, and commercial complexes across Canada.

Square Columns

Square columns offer clean lines, modern aesthetics, and exceptional structural performance. They are most frequently used in warehouses, office buildings, and retail construction.

Circular Columns

These columns are often chosen for architectural applications where design visibility matters—such as malls, cultural centers, and stadiums. Their circular shape distributes loads evenly, improving strength and stability.

Architectural Finishes

Columns can be cast with decorative patterns, polished surfaces, or exposed aggregates. This flexibility helps architects achieve both structural and visual goals simultaneously.

Usage

- Shopping centers

- Industrial manufacturing plants

- Multi-storey buildings

- Parking structures

5. Precast Stairs & Landings

Precast stairs offer unmatched durability and quick installation, making them ideal for projects requiring uniformity and speed. They are manufactured with precision to ensure safe rise-and-run ratios and slip-resistant surfaces.

Straight Stairs

Designed for commercial buildings, residential developments, and public facilities. They arrive ready for grouting and installation, significantly reducing build time.

L-Shaped or U-Shaped Stairs

These configurations provide safe directional transitions and are commonly used in hotels, schools, and apartment complexes.

Benefits for Fast Construction Schedules

- Factory-cast uniformity ensures consistent quality

- Non-slip options available for enhanced safety

- Minimal on-site labor required

- Ideal for phased or fast-track projects

6. Precast Foundation Elements

Precast foundations offer a reliable alternative to traditional poured footings, especially in projects where soil conditions, timelines, or weather create challenges. They help reduce onsite curing time and enhance structural performance.

Precast Footings

Designed for rapid placement and precise load distribution. They eliminate the need for forming and significantly reduce installation time.

Precast Grade Beams

These beams transfer loads between footings and provide structural support for walls and columns. Their controlled manufacturing improves alignment and structural consistency.

Precast Piles & Pile Caps

Used in areas requiring deep foundations. They offer superior durability and simplify the process of creating rigid support systems in challenging soil conditions.

7. Custom Precast Concrete Components

Beyond standard walls, slabs, and beams, modern precast technology allows for fully customized concrete solutions. These elements enhance functionality, safety, and design aesthetics.

Utility Boxes, Trenches & Vaults

Used in infrastructure, electrical, and water management systems. Precast ensures watertight performance and long-term reliability.

Retaining Walls & Barriers

These elements provide soil retention, traffic separation, and landscape stabilization. They are designed to withstand high lateral pressures and harsh environments.

Architectural Custom Precast

Includes decorative façades, cladding, and artistic components. Designers can incorporate patterns, colors, and textures.

Site Furnishings

Benches, planters, bollards, and other accessories that enhance outdoor spaces with durable, low-maintenance materials.

How Precast Concrete Elements Are Manufactured

The manufacturing process is what differentiates precast concrete from all other building systems. By combining engineering expertise with specialized equipment, manufacturers like Omega Precast deliver elements with exceptional durability and accuracy.

CAD Design & Engineering

Every precast element begins with detailed CAD drawings that specify dimensions, reinforcement layouts, tolerances, and project requirements.

Steel Reinforcement Preparation

Rebar cages or mesh reinforcements are assembled based on structural loads and design specifications.

Mold Preparation & Casting

Precision molds ensure each element matches exact dimensions. High-performance concrete is poured and vibrated to eliminate air pockets.

Curing in Controlled Conditions

Elements are cured using steam, heat, or advanced climate-controlled systems, ensuring consistent strength and reduced defects.

Finishing & Quality Control

Panels and structural pieces undergo careful inspection, surface finishing, and certification according to Canadian CSA standards.

Delivery & On-Site Installation

The finished components are shipped to the job site and installed using cranes, reducing total construction time significantly.

Choosing the Right Precast Supplier in Canada

With many manufacturers across the country, selecting the right precast supplier can greatly impact project outcomes. Consider the following factors:

Look for CSA-Certified Manufacturing

Certification ensures compliance with Canadian building codes and structural requirements.

Review Production Capacity

A dependable supplier can meet deadlines, accommodate large orders, and manage complex architectural designs.

Check Experience in Similar Projects

Past work in commercial, industrial, or multi-residential fields indicates specialization and reliability.

Request Samples or Case Studies

Case studies provide insight into quality, consistency, and long-term performance.

Benefits of Working With Omega Precast

- Modern manufacturing facilities with advanced curing technologies

- Canada-wide delivery and rapid project turnaround

- Experienced engineering and production team

- Custom design solutions for any application

Cost Factors for Precast Concrete Elements

The cost of precast concrete varies depending on several variables. Understanding these factors helps builders estimate budgets more accurately.

Material Strength & Reinforcement

Higher PSI concrete and additional rebar increase structural performance—and cost.

Dimensions & Complexity

Large or intricate pieces require more labor, mold preparation, and engineering.

Finishes (Smooth, Exposed, Architectural)

Premium aesthetic finishes may increase production time and material use.

Transportation Distance

Shipping precast across long distances impacts total project cost, especially in remote areas.

Installation Requirements

Cranes, lifting hardware, and specialized installation crews also affect final pricing.

Frequently Asked Questions

Which precast elements are most common in Canada?

Walls, slabs (especially hollow-core), beams, columns, and stairs are the most frequently used elements in Canadian commercial and industrial projects.

How long do precast concrete elements last?

With proper maintenance, precast elements typically last between 75 and 100 years.

Can precast be customized for my project?

Yes. Precast can be molded, reinforced, textured, and colored to meet structural and architectural requirements.

Are precast walls insulated?

Insulated sandwich panels provide high R-values and are ideal for energy-efficient buildings in cold climates.

Is precast more expensive than cast-in-place?

Upfront costs may be similar, but precast saves money long-term through reduced labor, faster installation, fewer delays, and lower maintenance.

Conclusion: Build Faster & Better With Precast Concrete

Precast concrete offers unmatched strength, consistency, and efficiency—making it one of the most reliable building systems in modern construction. From walls and slabs to beams, columns, stairs, and custom components, each precast element plays a crucial role in creating durable, high-performance structures across Canada.

By understanding the differences between precast elements, developers and contractors can make informed decisions and choose solutions that meet both functional and architectural needs. When paired with the expertise of a trusted supplier like Omega Precast, precast construction becomes the fastest and most cost-effective approach for projects of any scale.

By comparing different types of precast concrete, builders can optimize performance, reduce costs, and streamline construction timelines.

Ready to Start Your Next Project?

Contact Omega Precast today for fast, reliable, and professional precast concrete manufacturing anywhere in Canada. Our team is ready to help you turn your project into reality.