The global construction industry is entering one of the most transformative periods in decades. With rising infrastructure investments, tighter sustainability standards, and increasing pressure to deliver projects faster, the demand for precast concrete is accelerating at a record pace. As we move into 2025 and beyond, precast concrete is no longer just an alternative to traditional cast-in-place methods—it is becoming a strategic construction solution for governments, developers, and industry leaders worldwide. This shift is best understood by examining the differences between precast concrete and cast-in-place construction methods.

In this in-depth market outlook, we explore where the precast concrete industry is headed, which factors are shaping its rapid expansion, and how companies like Omega Precast are poised to serve the evolving needs of the Canadian and global market.

Introduction: Why Precast Concrete Is Entering a High-Growth Era

The global shift toward efficiency-based construction practices is creating extraordinary momentum for precast concrete. The method’s ability to reduce on-site labor, accelerate timelines, and ensure consistent quality makes it a cornerstone of modern development strategies.

Across the world, contractors and governments face similar challenges: labor shortages, escalating material costs, and the urgent need to deliver infrastructure and housing at scale. Precast concrete solves these challenges by moving critical production off-site into controlled manufacturing environments—something traditional cast-in-place methods cannot match.

At Omega Precast, we’ve seen firsthand how Canadian developers and industrial clients increasingly rely on precast to achieve predictable schedules, meet regulatory standards, and reduce project risks. This shift is a key component of the transformative precast concrete market 2025 landscape, which we will explore in this outlook.

Global Precast Concrete Market Overview for 2025+

Current Market Size (2024 Baseline)

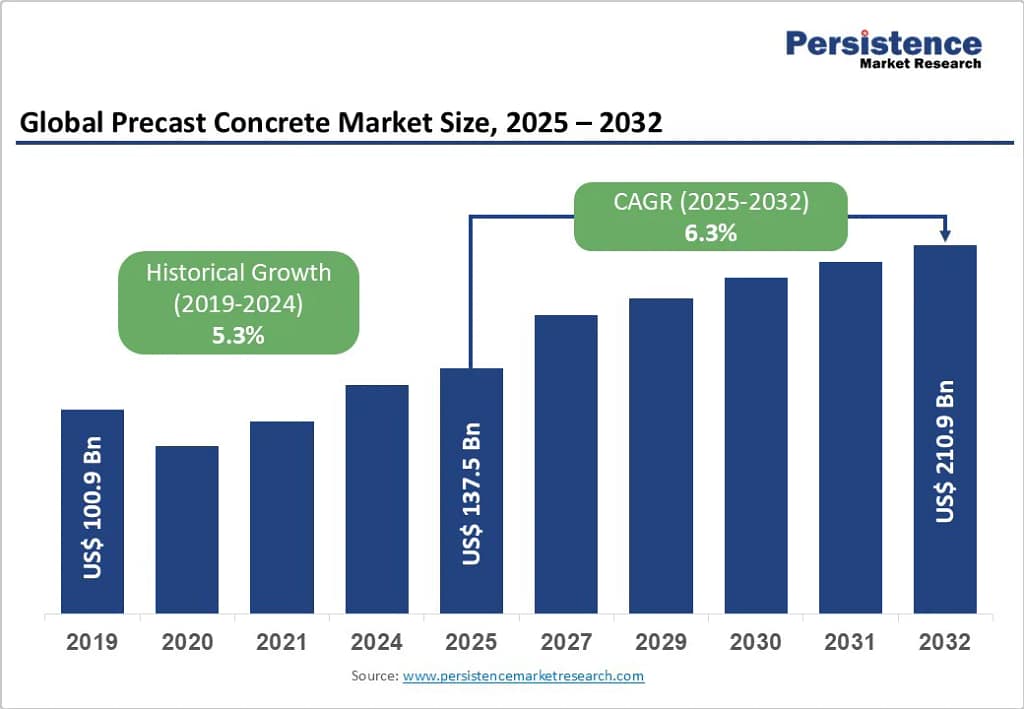

According to multiple industry analyses, the global precast concrete market surpassed an estimated $140–$150 billion USD in 2024. Growth remains strong across commercial, residential, industrial, and public infrastructure sectors, setting the stage for significant expansion in the years ahead.

- 2024–2032 Forecast CAGR: Approximately 5.5%–7.2% globally, underscoring the strong momentum of the precast concrete market 2025

- Highest growth regions: North America, Asia-Pacific, and Western Europe

- Main drivers: urban development, modular construction, public infrastructure investment

These numbers position precast concrete as one of the fastest-growing segments in the building materials industry. This establishes a robust foundation for the projected expansion of the precast concrete market 2025.

Expected Market Size in 2025 and 2030

By 2025, the precast concrete market is projected to reach $160–$170 billion USD, following demand increases in transportation infrastructure, utility structures, warehousing, and multi-family housing.

The precast concrete market 2025 is positioned at the beginning of this remarkable growth cycle, bridging current performance with future potential.

Looking further ahead, by 2030 the market is expected to exceed $210–$230 billion USD, with Asia-Pacific accounting for over 40% of the global demand, driven by massive urbanization and public megaprojects.

North America—especially Canada—is positioned for continued growth due to government investment in highways, bridges, water management systems, and industrial expansion.

Key Sectors Driving Demand Globally

The precast concrete market is expanding across nearly every construction sector, but several stand out due to accelerated growth:

These sectors are critical growth engines for the precast concrete market 2025:

- Residential: Affordable housing, modular homes, and high-density urban developments.

- Commercial: Warehouses, retail plazas, office buildings, distribution centers.

- Industrial: Manufacturing plants, utility vaults, mining infrastructure, and logistics hubs.

- Public Infrastructure: Bridges, tunnels, stormwater systems, transit stations.

- Energy & Utilities: Electrical vaults, water treatment structures, precast foundations.

These applications demonstrate how versatile precast solutions have become in supporting both private and public construction needs.

Top Market Drivers Propelling Precast Concrete Growth

1. Fast-Track Construction Needs

Speed is the new currency of construction. Precast concrete dramatically reduces project durations because components are manufactured off-site while site preparation happens simultaneously. Builders can complete foundations, walls, and structural components in weeks instead of months.

In 2024, McKinsey research noted that modular and prefabricated building approaches—including precast—can reduce timelines by 20–50%. This advantage becomes crucial for large-scale housing projects and industrial developments.

This speed advantage is a cornerstone of the precast concrete market 2025 value proposition.

2. Labor Shortages Driving Industrialized Building Methods

Globally, the construction labor shortage has reached unprecedented levels. Moving more work into factories allows companies to reduce reliance on unpredictable on-site labor. Precast plants use trained teams, automation, and controlled production processes to fill this gap.

For Canadian contractors, this shift is especially important as skilled labor costs continue rising each year.

This trend is fundamentally reshaping the labor dynamics of the precast concrete market 2025.

3. Sustainability & Energy Efficiency Targets

As the world moves toward stricter carbon-reduction goals, precast concrete offers a measurable path to sustainability:

- Less material waste during production

- Longer service life and durability

- Lower lifecycle emissions

- Recyclable and reusable components

Innovative mixes, such as low-carbon cement blends, are further improving environmental performance. Environmental performance is increasingly defining the competitive edge within the precast concrete market 2025.

4. Demand for Affordable Housing

Countries across the world face unprecedented housing shortages. Precast concrete enables the rapid creation of multi-unit residential buildings without sacrificing quality or safety.

With modular housing expanding in Canada and the U.S., precast is becoming the structural backbone for fast, scalable residential development.

Housing demands directly fuel the residential segment growth in the precast concrete market 2025.

5. Massive Government Infrastructure Spending

Public infrastructure spending has surged globally. From highway expansions to wastewater facilities, precast concrete structures—manholes, pipes, culverts, retaining walls—play essential roles in modernizing communities.

For example, Canada’s Investing in Canada Infrastructure Program continues to channel billions of dollars toward public projects, further boosting precast demand.

This represents the largest single catalyst for the precast concrete market 2025 expansion.

6. Quality Control & Reduced On-Site Risks

Producing structural elements in controlled environments ensures consistent curing, durability, and compliance with engineering standards. Precast also minimizes disruptions caused by weather, on-site accidents, and scheduling conflicts.

As one industry expert put it: “Controlled production environments are the future of safe, predictable construction.”

This provides a compelling risk-mitigation strategy throughout the precast concrete market 2025.

Market Trends to Watch in 2025 and Beyond

Rise of Modular & Prefabricated Mega-Projects

A defining feature of the precast concrete market 2025 is the rise of modular mega-projects. From large residential complexes to industrial parks, modular construction is setting new benchmarks for efficiency. Precast concrete plays a key role in delivering these projects quickly and safely.

Developers are embracing hybrid systems that combine precast walls, slabs, beams, and steel components to accelerate assembly.

Digital Twins, BIM, and AI in Precast Manufacturing

Digital transformation is fundamentally reshaping the precast concrete market 2025, moving beyond adoption to full integration. Tools like Building Information Modeling (BIM), 3D scanning, robotics, and digital twins are reducing errors, improving collaboration, and setting new standards for efficiency that will define the precast concrete market 2025.

AI-based software is also helping optimize material use, schedule production, and predict quality variations—creating smarter, more efficient precast plants.

Low-Carbon & Green Precast Materials

Sustainability innovations are becoming standard requirements across the precast concrete market 2025. Low-carbon cement formulations, supplementary cementitious materials (SCMs), and recycled aggregates are becoming standard in many markets. These innovations help countries meet climate targets while preserving strength and durability.

Advanced Reinforcement Technologies

Material science advancements are enhancing capabilities within the precast concrete market 2025. Fiber-reinforced concrete (FRC), GFRP rebar, and post-tensioned precast systems are gaining popularity for their flexibility, corrosion resistance, and reduced maintenance needs.

Customizable Architectural Precast Demand

Design possibilities are expanding the application scope of the precast concrete market 2025. Architects increasingly turn to precast to achieve unique façades, textures, and shapes. From university campuses to high-rise buildings, aesthetic precast panels allow creative architectural expression while preserving structural integrity.

Expansion of Automated Production Facilities

Manufacturing automation is increasing capacity for the precast concrete market 2025. Automation is transforming the precast industry. Facilities equipped with robotics, automated formwork, and precision casting technologies can increase throughput by 20–40% while reducing human error.

North America and Europe are leading the transition to smart precast factories—and Canada is quickly advancing in this direction.

Regional Market Forecasts

North America Outlook (Canada & United States)

The North American segment of the precast concrete market 2025 shows particular strength in infrastructure rehabilitation, industrial development, and e-commerce warehousing, cementing its position as one of the most stable and rapidly growing markets globally. In 2025, demand is projected to rise steadily due to increased infrastructure rehabilitation, industrial development, and the surge in e-commerce warehousing.

Canada, in particular, is experiencing strong momentum. Aging infrastructure across provinces—combined with rising population density in major cities like Edmonton, Calgary, Vancouver, and Toronto—creates a long-term need for durable, fast-install precast systems.

- Major demand drivers: transportation upgrades, water management systems, industrial expansions

- Key opportunities: utility precast, retaining walls, bridge components, precast foundations

- Competitive advantage: local manufacturers like Omega Precast with fast turnaround times

Europe Outlook

European contributions to the precast concrete market 2025 emphasize low-carbon construction and circular materials is pushing precast adoption forward. Countries such as Germany, the Netherlands, and the Nordic states lead the way with highly automated precast plants, strong regulatory frameworks, and a preference for modular building systems.

European construction firms are also adopting innovative technologies such as carbon-capture cement, digital twin monitoring, and 3D precast printing—advancements that will shape global standards in the coming decade.

Asia-Pacific Growth Outlook

The Asia-Pacific region dominates global precast consumption due to urbanization, government-funded megaprojects, and housing demands in China, India, Indonesia, and Vietnam. Rapid population expansion requires construction methods that are fast, affordable, and scalable.

APAC’s precast market is expected to grow at a CAGR exceeding 6–8% through 2030, driven by mega-infrastructure such as transit systems, bridges, and smart cities.

Middle East & Africa Outlook

Large infrastructure investments, tourism-driven mega-developments, and industrial diversification projects are fueling precast demand across the Middle East. Countries like UAE, Saudi Arabia, and Qatar continue adopting precast to reduce construction time and improve durability in extreme climates.

Africa is also emerging as a growth region, with precast used increasingly for affordable housing, public infrastructure, and utility systems.

Precast Concrete Applications with the Fastest Growth Rates

Infrastructure (Bridges, Tunnels, Highways)

Infrastructure remains the top global consumer of precast concrete. Durable structures such as bridge girders, culverts, barriers, and railway components require precision and long-term strength—areas where precast excels.

Industrial Buildings & Warehouses

The explosion of e-commerce and logistics is fueling demand for large-scale warehouse construction. Precast walls, slabs, and structural elements shorten build times and offer superior fire resistance, making them ideal for industrial projects.

Residential Multi-Unit Buildings

High-rise and multi-family housing projects benefit from precast’s speed, acoustic performance, and structural durability. Many countries now rely on precast modular systems to build affordable housing at scale.

Public Buildings (Hospitals, Schools, Transit)

Government institutions prefer precast due to predictable costs, long service life, and minimal maintenance. Schools, healthcare facilities, and transit hubs increasingly use precast wall panels, beams, and roofing systems.

Energy Sector (Utility Vaults, Electrical, Water Management)

Precast utility vaults, transformer pads, pump stations, and electrical enclosures form the backbone of modern energy distribution networks. Growth in renewable energy infrastructure will continue increasing demand for specialized precast components.

Challenges Affecting the Precast Concrete Market

Supply Chain Volatility

Fluctuations in cement, steel, and logistics costs remain a challenge. While precast factories are highly efficient, they still rely on stable material supply chains.

Transportation Costs

Because precast elements are heavy, transportation distance can impact project economics. Local manufacturers, like those in Canada, often have a major competitive advantage due to proximity to project sites.

Skilled Labor Shortages in Manufacturing

While precast reduces on-site labor, it still requires trained technicians, engineers, and plant operators. As demand grows, there is a global push to develop stronger training pipelines.

Design Complexity & Customization Demands

Architectural and project-specific customization continues to rise. While precast can achieve a high degree of customization, it requires advanced equipment, experienced engineers, and precise molds.

Environmental Regulations

New carbon regulations may increase costs for high-emission materials. However, they also drive innovation toward greener, more efficient precast solutions.

Opportunities for Growth in the Precast Industry

Despite challenges, the precast concrete market 2025 presents significant growth opportunities:

Green Construction & Carbon Reduction Solutions

Governments and companies worldwide are adopting strict environmental goals. Precast’s low-waste production and long service life make it a natural fit for green building standards.

Off-Site Construction Acceleration

Off-site building methods are projected to grow significantly over the next decade. Precast provides the structural backbone for modular hotels, apartments, and industrial buildings.

Smart Factories & Automation

Automation reduces production time, minimizes human errors, and improves consistency. As more manufacturers adopt robotics, AI scheduling, and digital quality control, industry output will rise significantly.

Demand for Resilient, Disaster-Resistant Structures

Precast concrete’s durability against fire, earthquakes, and extreme weather makes it ideal for resilient infrastructure planning—one of the most important global development priorities.

Comparison Table: Precast Concrete vs Cast-In-Place (2025 Outlook)

| Criteria | Precast Concrete | Cast-In-Place Concrete |

|---|---|---|

| Speed of Construction | Very fast; parallel site and factory work | Slow; fully dependent on on-site labor |

| Quality Control | High; factory-controlled curing and production | Variable; dependent on weather and site conditions |

| Labor Use | Low; minimal on-site workforce needed | High; requires large skilled crews |

| Environmental Impact | Lower waste, more efficient materials | Higher emissions and material waste |

| Cost Predictability | Very predictable | Moderate; more variables |

| Suitability for Modular Projects | Excellent | Limited |

What This Means for Canadian Construction (Omega Precast Insight)

Opportunities Across Alberta, Saskatchewan, B.C., and Ontario

Canada’s infrastructure spending plans and housing development targets make it one of the strongest markets for precast adoption. From major highway twinning projects to new residential expansions, precast systems offer unmatched speed and durability.

Industrial & Commercial Precast Demand in Canada

Western Canada’s rapid industrial growth—especially in logistics, energy, and manufacturing—continues to drive demand for precast walls, foundations, utility vaults, and structural components.

Why Developers Prefer Local Manufacturers Like Omega Precast

Local production ensures faster delivery, reduced transportation costs, and direct project support. Omega Precast’s modern manufacturing capabilities and industry expertise position us as a leading partner for contractors across Canada.

How Omega Precast Supports Canada’s Precast Growth

Modern Equipment & Automated Production Lines

Our facility uses advanced molds, automated casting systems, and optimized curing environments to produce reliable precast components year-round.

Strict Quality Assurance & CSA/National Standards Compliance

Every product undergoes rigorous testing to ensure long-term performance, structural integrity, and compliance with Canadian standards.

Fast Turnaround & Predictable Delivery Schedules

With efficient production processes and strong logistics coordination, Omega Precast ensures timely delivery for projects of any size.

Wide Range of Precast Products

We manufacture everything from utility vaults to walls, slabs, barriers, and custom-designed precast elements.

Capability for Custom Precast Projects

Our engineering team works closely with contractors, architects, and developers to create tailored precast solutions that meet unique project requirements.

Summary & Key Takeaways

The global precast concrete market is entering a period of unprecedented growth. With its speed, sustainability, and reliability, precast is becoming essential for infrastructure, industrial, and residential projects worldwide. North America—and especially Canada—is poised to benefit enormously from this shift.

As demand accelerates, Omega Precast remains committed to supporting contractors with high-quality products, modern manufacturing, and industry-leading expertise.

Contact Omega Precast Today

Need reliable precast concrete solutions for your next project? Our team is ready to support you with fast turnaround times, modern production capabilities, and expert engineering.

Reach out today to request a quote or discuss your project needs.

Frequently Asked Questions (FAQ)

What is the outlook for precast concrete in 2025?

The outlook is highly positive, with strong global demand driven by infrastructure projects, modular construction, and sustainability initiatives.

Which countries are driving precast concrete growth?

China, India, Canada, the United States, Germany, and several Middle Eastern countries are leading the market due to major development investments.

What industries are adopting precast the fastest?

Infrastructure, industrial construction, housing, and energy sectors are experiencing the highest adoption rates.

How does precast reduce construction time?

Precast components are manufactured off-site, allowing simultaneous site preparation and installation, reducing timelines by up to 50%.

Is precast concrete sustainable?

Yes. Precast concrete reduces waste, uses materials efficiently, and supports long service life and energy-efficient designs.