Precast concrete eco-friendly solutions are no longer a “nice-to-have” in construction—they’re becoming a requirement. From stricter building codes to rising material costs and climate commitments, builders and developers across Canada are under growing pressure to choose environmentally responsible materials. Concrete, however, often finds itself at the center of debate. Many people ask the same question: is precast concrete eco-friendly, or is it just another carbon-heavy building material?

The answer isn’t as simple as yes or no. Like most construction materials, the environmental impact of concrete depends on how it’s produced, how it’s used, and how long it lasts. This article takes a practical, real-world look at precast concrete sustainability—examining its manufacturing process, environmental benefits, lifecycle performance, and how it compares to other building methods. Drawing on industry data and hands-on manufacturing experience at Omega Precast, we’ll help you decide whether precast concrete aligns with modern green building goals.

What Makes Precast Concrete Eco-Friendly in Construction?

Defining Sustainability in Building Materials

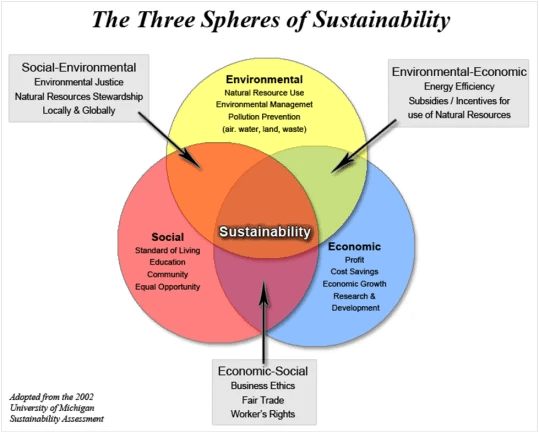

In construction, the term “eco-friendly” goes far beyond a single metric like carbon emissions. A truly sustainable building material is evaluated across multiple dimensions, including:

- Embodied carbon – greenhouse gas emissions generated during material extraction, manufacturing, and transportation

- Resource efficiency – how efficiently raw materials are used and how much waste is produced

- Durability and lifespan – how long the material performs without major repairs or replacement

- Energy performance – how the material contributes to operational energy efficiency

- End-of-life options – recyclability or reuse potential

Judging sustainability based only on one factor—such as cement emissions—often leads to misleading conclusions. That’s why lifecycle thinking is critical when asking whether precast concrete is eco-friendly.

Green Building Standards and Benchmarks

In Canada, sustainability is commonly measured against recognized frameworks such as LEED (Leadership in Energy and Environmental Design), Net-Zero Energy standards, and emerging ESG (Environmental, Social, and Governance) criteria. These systems emphasize long-term performance, durability, and reduced environmental impact over the entire life of a structure.

Precast concrete frequently supports these benchmarks by contributing to thermal mass, reduced construction waste, and long service life—factors that are often undervalued in short-term assessments.

How Precast Concrete Is Manufactured

Controlled Manufacturing Environment

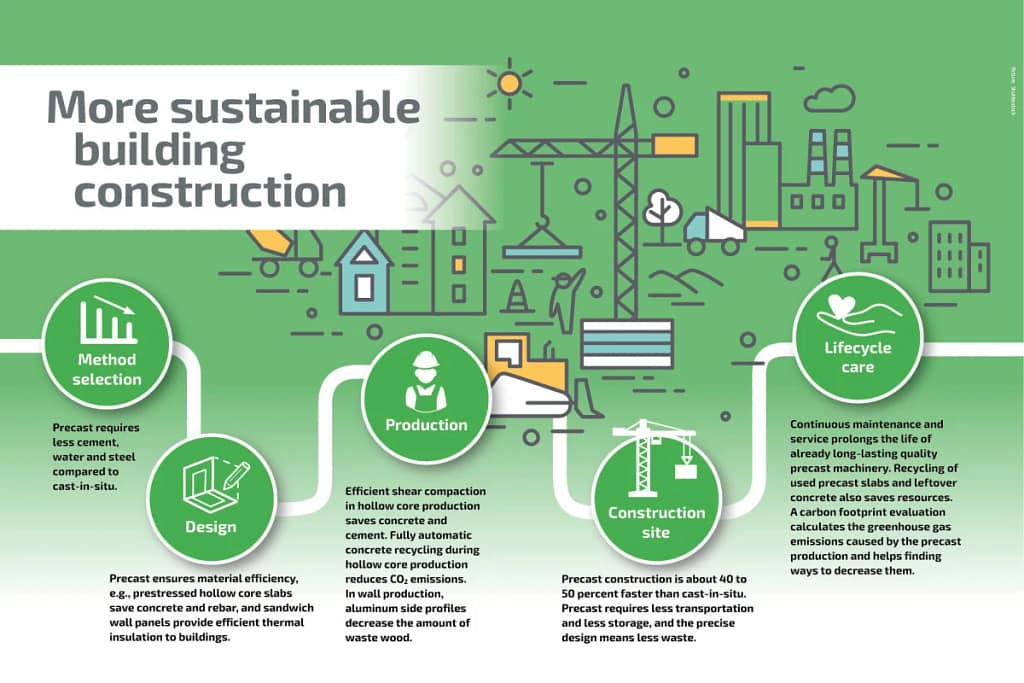

One of the biggest sustainability advantages of precast concrete lies in where it is made. Unlike cast-in-place concrete, which is mixed and poured on construction sites exposed to weather, variability, and inefficiency, precast concrete is manufactured in a controlled plant environment. This controlled approach is a key reason why precast concrete eco-friendly systems outperform traditional cast-in-place methods in sustainability metrics.

This controlled setting allows manufacturers to:

- Precisely measure raw materials

- Optimize concrete mix designs

- Reuse formwork hundreds or thousands of times

- Reduce rejected or over-poured material

According to industry studies, factory-controlled concrete production can reduce material waste by up to 30–50% compared to traditional site-cast methods. Less waste means fewer resources extracted and less material sent to landfills.

Role of Modern Equipment and Automation

Modern precast plants rely on advanced batching systems, automated form cleaning, and optimized curing processes. These technologies significantly improve consistency while lowering energy use per unit produced.

For example, controlled curing environments allow concrete to reach required strength faster and more reliably, reducing the need for rework or demolition—both major contributors to construction waste and emissions.

Professional Manufacturing Practices at Scale

Experienced precast manufacturers combine skilled teams with modern equipment to ensure quality and efficiency. Consistency matters: fewer defects mean fewer replacements, lower material consumption, and reduced environmental impact over time.

In Canada’s challenging climate, this consistency is especially important. Producing concrete in controlled conditions avoids cold-weather inefficiencies, excess cement usage, and energy-intensive winter site pours.

Environmental Benefits of Precast Concrete

Reduced Material Waste

Reduced waste is one of the strongest arguments supporting precast concrete eco-friendly construction practices. Precast concrete directly addresses this issue through:

- Reusable steel or fiberglass forms

- Accurate batching and placement

- Minimal on-site cutting or modification

Excess concrete from precast plants is often crushed and reused as aggregate, further closing the material loop. This level of waste control is extremely difficult to achieve on traditional job sites.

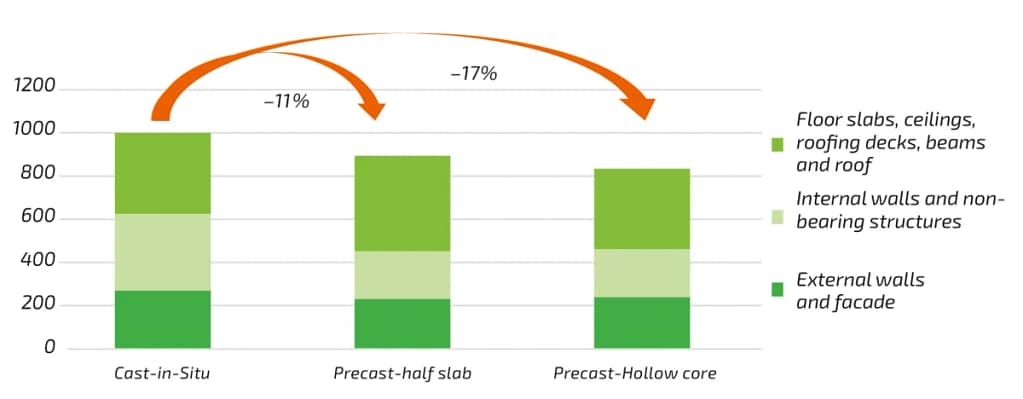

Lower Carbon Emissions Compared to Cast-in-Place

While cement production is undeniably carbon-intensive, precast concrete can significantly reduce overall project emissions when compared to cast-in-place construction. Why? Because emissions don’t come from materials alone—they also come from inefficiency.

Precast construction reduces:

- Repeated concrete truck deliveries

- On-site generators and heavy equipment runtime

- Extended construction schedules

A study published in the Journal of Cleaner Production found that industrialized construction methods, including precast concrete, can reduce total construction-related emissions by 20–40% compared to conventional building practices.

Energy Efficiency in Production

Energy use in precast manufacturing is optimized through economies of scale. Producing multiple units in one facility allows energy inputs—such as heating and curing—to be distributed more efficiently per cubic metre of concrete.

Additionally, faster installation times on site reduce overall project energy use, helping developers meet sustainability targets without sacrificing performance or structural integrity.

Lifecycle Sustainability: Why Precast Concrete Eco-Friendly Design Lasts Longer

Durability and Long Service Life

One of the most overlooked aspects of sustainability is durability. A material that lasts twice as long effectively cuts its environmental impact in half when measured over time.

Precast concrete structures routinely achieve service lives of 50 to 100 years or more. In Canada, precast concrete performs exceptionally well under freeze–thaw cycles, moisture exposure, and heavy structural loads.

Fewer repairs and replacements mean:

- Lower lifetime material consumption

- Reduced maintenance emissions

- Less disruption to occupants and communities

End-of-Life Recyclability

At the end of its service life, precast concrete is not waste—it is a resource. Concrete elements can be crushed and reused as aggregate in new concrete, road base, or other construction applications.

Steel reinforcement is also fully recyclable, supporting circular economy principles increasingly adopted in sustainable construction policies.

Why Lifecycle Assessment (LCA) Matters

Lifecycle assessment (LCA) evaluates environmental impact from raw material extraction through manufacturing, use, and end-of-life. When assessed using LCA, precast concrete often outperforms materials that appear “greener” at first glance but require frequent replacement or intensive maintenance.

Conclusion

When evaluated through lifecycle assessment, durability, and waste reduction, precast concrete eco-friendly construction clearly aligns with modern sustainability goals. For long-term performance in Canada’s climate, precast offers one of the most responsible building solutions available today.