Modern construction projects are under more pressure than ever. Developers need buildings delivered faster. Architects demand design flexibility. Owners expect long-term durability and energy efficiency. And in Canada’s challenging climate, wall systems must perform reliably year after year. This is where precast concrete wall panels have become a preferred solution across commercial, industrial, and institutional construction.

Precast wall panels combine speed, strength, and precision by shifting much of the construction process from the jobsite to a controlled manufacturing environment. In this guide, we’ll break down what precast concrete wall panels are, how they’re made, and the major types available today—helping you determine which system is best suited for your project.

What Are Precast Concrete Wall Panels?

Definition and Core Concept

Precast concrete wall panels are large, engineered concrete elements that are manufactured off-site in a specialized precast facility and then transported to the construction site for installation. Unlike cast-in-place concrete walls, which are formed and poured entirely on site, precast panels are produced under controlled conditions to ensure consistent quality, strength, and finish.

These panels can serve multiple roles within a building envelope. Depending on their design, precast concrete wall panels may be structural (load-bearing), non-structural (cladding), insulated, or highly architectural. This versatility is one of the key reasons precast systems are widely used across Canada in everything from warehouses and offices to schools and multi-family developments.

How Precast Wall Panels Are Manufactured

The performance of precast concrete wall panels begins in the plant. Manufacturing in a controlled environment allows for tighter tolerances, repeatable quality, and reduced exposure to weather-related delays. While specific processes vary by project, most precast wall panels follow a similar production workflow:

- Form and mold preparation: Steel or custom forms are cleaned, set, and treated with release agents to achieve precise panel dimensions.

- Reinforcement placement: Rebar, welded wire mesh, or embedded connection hardware is installed according to engineered shop drawings.

- Concrete casting: High-performance concrete mixes are poured and consolidated to eliminate voids and ensure strength.

- Curing and finishing: Panels cure under controlled conditions, allowing for consistent strength gain and surface quality.

- Quality control: Dimensional checks, surface inspections, and strength testing are conducted before shipment.

According to the Precast/Prestressed Concrete Institute (PCI), factory-controlled production can reduce material waste by up to 30% compared to traditional site-cast construction, while also improving consistency and long-term performance.

For project teams new to off-site construction, understanding key precast concrete terminology builders should know helps streamline coordination between designers, engineers, and installers.

Precast vs Cast-In-Place Concrete Walls

When comparing precast concrete wall panels to cast-in-place concrete walls, the differences go far beyond where the concrete is poured. Each system has its place, but precast offers several distinct advantages for projects where schedule certainty and quality control are critical.

| Factor | Precast Concrete Wall Panels | Cast-In-Place Concrete Walls |

|---|---|---|

| Construction Speed | Fast installation, parallel plant and site work | Sequential work, weather-dependent |

| Quality Control | Factory-controlled environment | Variable site conditions |

| Finish Consistency | High, repeatable finishes | Dependent on site workmanship |

| Weather Impact | Minimal | High, especially in cold climates |

For many Canadian projects facing tight timelines or winter construction constraints, precast concrete wall panels provide a more predictable and efficient solution.

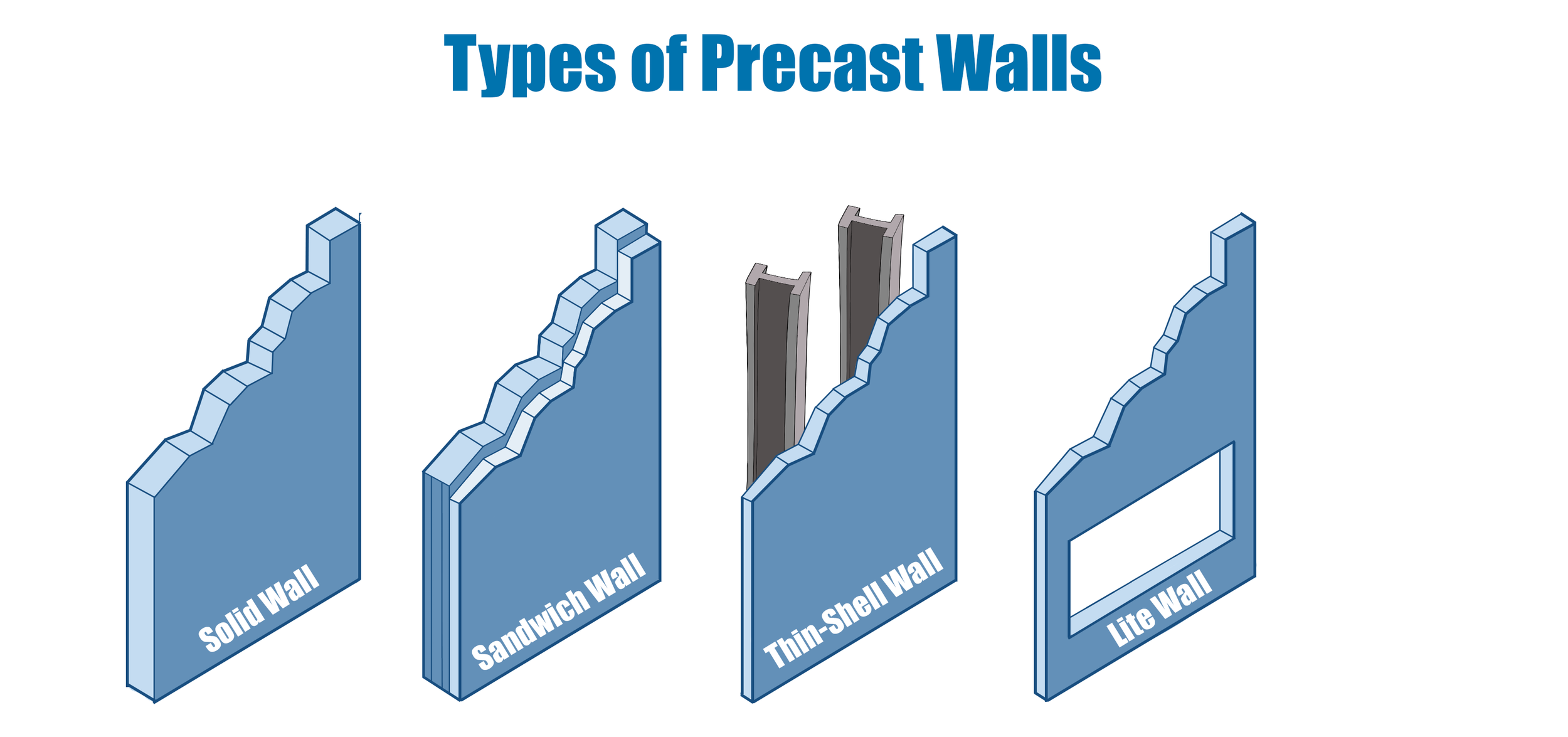

Main Types of Precast Concrete Wall Panels

Not all precast wall panels are the same. Understanding the different types of precast concrete wall panels is essential when selecting the right system for your building’s structural, thermal, and architectural requirements.

Selecting the right system depends on structural demands, insulation requirements, and aesthetics, which is why understanding types of precast concrete wall panels and their applications is essential during early design stages.

Load-Bearing Precast Wall Panels

Load-bearing precast concrete wall panels serve a structural function by supporting vertical loads from floors, roofs, or additional wall elements above. These panels are engineered to transfer loads directly to the foundation, often reducing or eliminating the need for separate structural framing.

Because they combine enclosure and structure into a single element, load-bearing precast walls are especially common in industrial buildings, parking structures, and mid-rise construction.

Key Advantages of Load-Bearing Panels

- Reduced structural steel or framing requirements

- Faster building enclosure and earlier interior work

- Excellent fire resistance and impact durability

Non-Load-Bearing (Cladding) Precast Wall Panels

Non-load-bearing precast concrete wall panels, often referred to as cladding panels, are designed primarily as an exterior envelope rather than a structural element. These panels are supported by the building’s structural frame while providing weather protection, insulation options, and architectural expression.

This type of precast wall panel is commonly used in commercial offices, retail developments, and mixed-use projects where design flexibility is a priority.

Common Applications

- Office buildings and corporate campuses

- Retail plazas and shopping centers

- Institutional and civic architecture

Architectural Precast Wall Panels

Architectural precast concrete wall panels elevate precast from a purely functional system to a design-forward building solution. These panels allow architects to achieve custom textures, colors, reveals, and patterns while maintaining the durability of concrete.

Because finishes are produced in controlled conditions, architectural precast can replicate stone, brick, or custom forms with a high degree of consistency—often at a lower lifecycle cost than traditional materials.

Popular Architectural Finishes

- Smooth and polished concrete finishes

- Sandblasted or acid-etched surfaces

- Exposed aggregate textures

- Brick-faced or patterned precast panels

Architectural precast wall panels are frequently specified for civic buildings, educational facilities, and high-profile commercial projects where aesthetics and longevity must work together.

Developers working in Western Canada often reference a complete guide to precast concrete products to ensure materials are suited to Alberta’s climate, codes, and logistics.

Insulated Precast Concrete Wall Panels

Insulated precast concrete wall panels—often referred to as sandwich panels—combine structural performance with high thermal efficiency. These panels typically consist of two concrete wythes separated by a rigid insulation core, mechanically connected to act as a composite system.

In Canada’s climate, insulated precast wall panels play a critical role in reducing energy consumption and improving occupant comfort. Continuous insulation within the panel helps minimize thermal bridging, contributing to improved building envelope performance.

Studies from the National Research Council of Canada (NRC) have shown that well-designed insulated precast wall systems can significantly reduce heating and cooling loads compared to traditional wall assemblies.

“Precast insulated wall panels allow designers to address structure, enclosure, and energy performance in a single, highly coordinated system,” notes a senior building envelope specialist with over 20 years of experience in cold-climate construction.

Solid Precast Concrete Wall Panels

Solid precast concrete wall panels are single-wythe panels made entirely of reinforced concrete without an integrated insulation layer. While they do not provide the same thermal performance as insulated sandwich panels, they excel in strength, durability, and mass—making them ideal for demanding environments.

These panels are commonly specified where structural performance, impact resistance, or fire protection is the primary concern rather than energy efficiency alone.

Ideal Applications for Solid Panels

- Industrial plants and heavy manufacturing facilities

- Utility buildings and infrastructure enclosures

- Firewalls, blast-resistant walls, and security structures

In industrial settings, solid precast concrete wall panels often outperform lighter wall systems by providing decades of service with minimal maintenance, even in harsh Canadian weather conditions.

Applications of Precast Concrete Wall Panels

The versatility of precast concrete wall panels allows them to be used across a wide range of building types. Their ability to combine structure, enclosure, and finish into a single system makes them especially valuable for projects focused on long-term performance and schedule certainty.

Commercial Buildings

In commercial construction, precast wall panels are widely used for office buildings, retail centres, hotels, and mixed-use developments. Fast installation helps developers bring properties to market sooner, while architectural precast finishes support strong brand identity and curb appeal.

For example, many Canadian retail developments rely on non-load-bearing architectural precast panels to achieve consistent façades across multiple tenant spaces while maintaining tight construction schedules.

Industrial and Warehouse Facilities

Industrial buildings benefit significantly from the durability and low maintenance requirements of precast concrete wall panels. High resistance to fire, moisture, and physical impact makes precast an ideal solution for warehouses, distribution centres, and manufacturing plants.

Load-bearing and solid precast panels are frequently used to reduce structural complexity while delivering long-span, high-clearance spaces.

Residential and Multi-Family Construction

In mid-rise residential and multi-family projects, precast concrete wall panels provide excellent acoustic separation, fire resistance, and long-term durability. Insulated precast panels are often used to meet increasingly strict energy codes while maintaining consistent exterior finishes.

Developers also benefit from reduced callbacks and lower lifecycle costs compared to traditional framed wall systems.

Institutional and Public Infrastructure

Schools, hospitals, and government buildings frequently specify precast wall panels due to their longevity and predictable performance. These facilities demand materials that can withstand decades of use with minimal disruption for repairs or replacements.

Precast concrete wall panels also support tight construction schedules, which is critical for public-sector projects with fixed opening dates.

Key Benefits of Precast Concrete Wall Panels

Speed of Construction

One of the most significant advantages of precast concrete wall panels is speed. Because panels are manufactured off-site while foundations and site work are underway, overall project timelines are shortened.

Once delivered, panels can be erected rapidly—often enclosing a building in days rather than weeks.

Quality Control and Consistency

Factory production allows for rigorous quality control that is difficult to achieve on a jobsite. Dimensional accuracy, concrete strength, and finish quality are all monitored closely, resulting in consistent outcomes across large projects.

Durability and Longevity

Concrete’s inherent resistance to fire, moisture, pests, and UV exposure gives precast wall panels a long service life. Many precast buildings remain in service for 50 years or more with minimal maintenance.

Energy Efficiency and Sustainability

Insulated precast concrete wall panels contribute to reduced energy consumption by providing continuous insulation and thermal mass. This can help stabilize interior temperatures and lower heating and cooling demands.

Additionally, precast manufacturing produces less waste and allows for optimized material use, supporting more sustainable construction practices.

Cost Predictability

Precast wall panels reduce the risk of weather delays, rework, and labour variability. For owners and developers, this translates into more predictable budgets and fewer surprises during construction.

Precast Wall Panels vs Other Wall Systems

| Wall System | Strength & Durability | Speed | Lifecycle Cost |

|---|---|---|---|

| Precast Concrete Wall Panels | Excellent | Fast | Low |

| Tilt-Up Concrete | Very Good | Moderate | Moderate |

| Steel Stud + EIFS | Moderate | Slow | Higher |

| CMU Block Walls | Good | Slow | Moderate |

Design and Engineering Considerations

Structural and Connection Design

Successful precast concrete wall panel systems rely on well-coordinated structural and connection design. Load paths, panel joints, and connection hardware must be engineered to accommodate gravity loads, wind loads, and seismic forces.

Transportation and Installation Planning

Panel size and weight must be coordinated with transportation regulations and site crane capacities. Early collaboration with a precast manufacturer helps optimize panel layouts and minimize installation challenges.

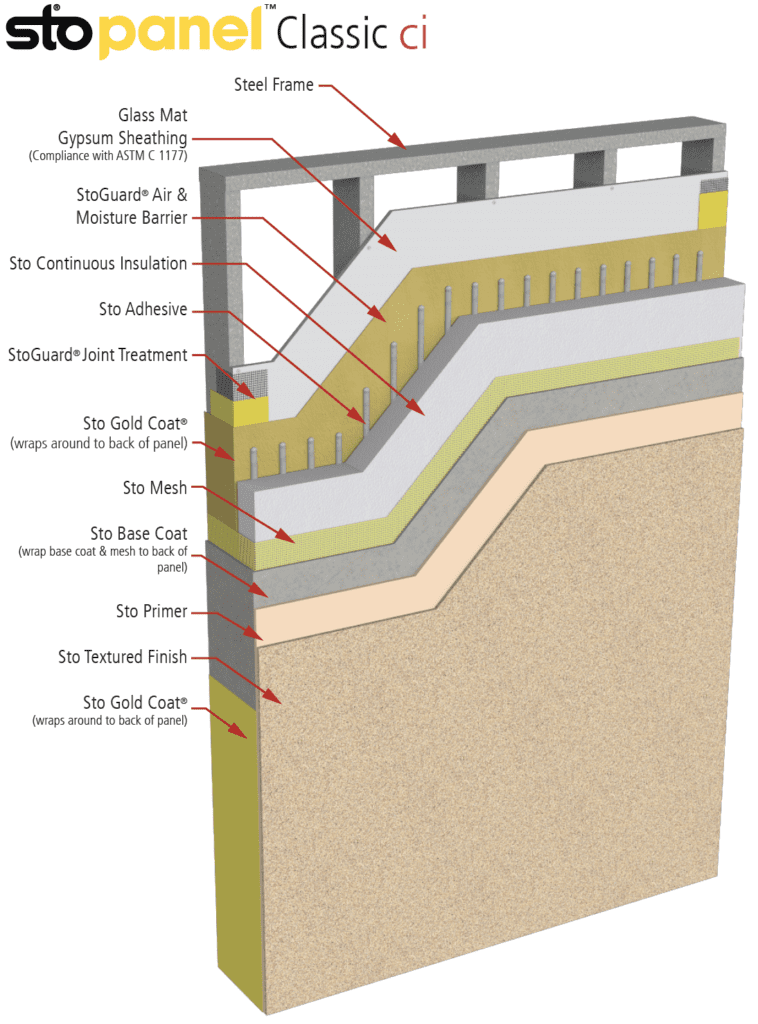

Building Envelope Performance

Proper detailing of air, water, and vapor barriers is essential. Precast wall panels can integrate these layers effectively when designed as part of a holistic building envelope strategy.

Why Choose Omega Precast for Wall Panels in Canada

Omega Precast provides precast concrete wall panels for projects across Canada, combining experienced engineering support with modern manufacturing capabilities. Our team works closely with developers, architects, and contractors to deliver wall systems that meet structural, architectural, and performance requirements.

- Nationwide service and logistics coordination

- Modern precast manufacturing facilities

- Custom architectural finishes and molds

- Reliable lead times and responsive project support

Frequently Asked Questions About Precast Concrete Wall Panels

How long do precast concrete wall panels last?

With proper design and installation, precast concrete wall panels can last 50 years or more, often outlasting many other building envelope systems.

Are precast wall panels energy efficient?

Yes. Insulated precast concrete wall panels offer excellent thermal performance and can help buildings meet or exceed energy code requirements.

Can precast wall panels be customized?

Absolutely. Architectural precast allows for a wide range of colors, textures, and finishes to match design intent.

Are precast wall panels suitable for Canadian climates?

Precast concrete wall panels perform exceptionally well in freeze-thaw environments and are commonly used throughout Canada.

Conclusion: Building Smarter with Precast Concrete Wall Panels

Precast concrete wall panels offer a powerful combination of speed, durability, design flexibility, and long-term value. By understanding the different types of panels and their applications, project teams can select wall systems that align with performance goals and budget expectations.

Whether you’re planning a commercial development, industrial facility, or institutional project, precast wall panels provide a proven, future-ready solution.

Ready to Get Started?

If you’re considering precast concrete wall panels for your next project, the team at Omega Precast is ready to help. Contact us today to discuss your requirements, request pricing, or start a technical consultation with our precast specialists.