Concrete has long been valued for its strength and durability, but in today’s fast-moving construction industry, weight, speed, and energy performance matter more than ever. As projects grow taller, tighter, and more sustainability-focused, traditional concrete can introduce challenges—higher structural loads, increased transportation costs, and longer installation timelines. This is where lightweight precast concrete has emerged as a powerful solution.

Across Canada, developers, architects, and contractors are increasingly turning to lightweight precast systems to reduce dead loads, improve thermal performance, and accelerate construction schedules—without sacrificing structural integrity. In this guide, we’ll explore what lightweight precast concrete is, the materials that make it possible, and why it plays a growing role in modern residential, commercial, and industrial construction.

What Is Lightweight Precast Concrete?

Definition & Key Characteristics

Lightweight precast concrete is a factory-manufactured concrete product designed to have a significantly lower density than conventional normal-weight concrete. While traditional concrete typically weighs around 2,300–2,400 kg/m³, lightweight precast concrete generally falls in the range of 1,400–1,900 kg/m³, depending on the mix design and materials used.

This reduced weight is achieved by replacing standard aggregates with lightweight alternatives or by introducing engineered voids within the concrete matrix. Despite being lighter, these elements are engineered to meet strict structural, fire, and durability requirements under Canadian building codes.

- Lower dead load on foundations and structural frames

- Improved thermal and acoustic performance

- Factory-controlled quality and dimensional accuracy

- Compatibility with structural and non-structural applications

Lightweight vs Traditional Precast Concrete

While both lightweight and traditional precast concrete are produced in controlled plant environments, their performance characteristics differ in important ways. The table below highlights the most relevant differences for designers and builders.

| Attribute | Traditional Precast | Lightweight Precast |

|---|---|---|

| Typical Density | 2,300–2,400 kg/m³ | 1,400–1,900 kg/m³ |

| Structural Load | Higher dead load | Reduced dead load |

| Thermal Performance | Moderate | Enhanced |

| Transportation Costs | Higher | Lower |

| Installation Speed | Standard | Faster handling and erection |

For projects where weight reduction, energy efficiency, or crane capacity are limiting factors, lightweight precast concrete offers clear advantages.

Why Lightweight Matters in Modern Construction

Modern construction is driven by efficiency. Lighter structural components reduce the size and cost of foundations, allow for longer spans, and enable faster installation—especially in urban or remote locations. In seismic regions, reducing mass can also help limit earthquake forces acting on a structure.

From a sustainability perspective, lighter elements often translate into lower transportation emissions and reduced material usage across the entire building system. For developers focused on lifecycle cost and environmental performance, these benefits can be decisive.

Materials Used in Lightweight Precast Concrete

Lightweight Aggregates

Lightweight aggregates form the backbone of many structural lightweight precast concrete systems. These aggregates are engineered or naturally occurring materials with internal porosity, allowing them to weigh less than conventional stone while still providing strength.

Expanded Clay, Shale & Slate (ESCS)

Expanded clay, shale, and slate—often referred to as ESCS—are produced by heating raw materials in a rotary kiln. This process causes the material to expand internally, creating a ceramic-like aggregate with excellent strength-to-weight characteristics.

ESCS aggregates are commonly used in structural lightweight precast panels, beams, and floor systems. According to industry data, structural lightweight concrete using ESCS can achieve compressive strengths exceeding 35 MPa, making it suitable for load-bearing applications in mid- and high-rise construction.

- High durability and freeze-thaw resistance

- Compatible with reinforced and prestressed concrete

- Widely accepted by Canadian engineers

Pumice & Natural Lightweight Aggregates

Pumice and other volcanic aggregates are naturally lightweight materials used in select precast applications. While they offer good insulation properties, their availability and strength can vary by region.

In practice, natural lightweight aggregates are more commonly used in non-structural or architectural precast elements rather than heavily loaded structural systems.

Structural lightweight concrete systems are defined under relevant CSA standards governing precast concrete in Canada.

EPS (Expanded Polystyrene) Concrete

EPS concrete replaces traditional aggregates with small expanded polystyrene beads, creating an ultra-lightweight concrete matrix. These systems are especially popular for wall panels and building envelopes where insulation is a priority.

Like all precast systems, lightweight concrete performs best when common precast mistakes are identified and avoided during design.

Composition & Mix Design

In EPS concrete, carefully graded polystyrene beads are blended with cementitious materials, admixtures, and water. The result is a highly workable mix with controllable density—often as low as 800–1,200 kg/m³.

Because EPS beads do not absorb water, mix design and curing processes must be tightly controlled in a precast environment to ensure uniform strength and finish quality.

Thermal & Acoustic Performance

One of the strongest advantages of EPS-based lightweight precast panels is thermal efficiency. EPS concrete panels can deliver significantly higher R-values than conventional concrete walls, helping projects meet or exceed Canadian energy codes.

In addition to thermal performance, the cellular structure of EPS concrete provides effective sound attenuation—making it suitable for multi-residential, institutional, and mixed-use buildings.

Autoclaved Aerated Concrete (AAC)

How AAC Is Manufactured

Autoclaved aerated concrete (AAC) is a distinct type of lightweight concrete produced by introducing air through a chemical reaction rather than lightweight aggregates. Aluminum powder reacts with lime and cement to create millions of microscopic air bubbles.

The material is then cured in a high-pressure steam autoclave, resulting in a uniform, lightweight product with excellent dimensional stability.

Structural & Fire Performance

AAC panels are non-combustible and can achieve fire resistance ratings of up to 4 hours, depending on thickness. While AAC is lighter than many aggregate-based systems, its structural capacity is generally lower, making it more suitable for low- to mid-rise construction.

For specific applications—such as infill panels, partitions, and low-rise structures—AAC offers a compelling balance of weight reduction, fire safety, and energy efficiency.

Energy performance benefits align with National Building Code of Canada requirements for thermal efficiency.

Manufacturing Process of Lightweight Precast Concrete

Mix Design & Quality Control

The performance of lightweight precast concrete begins with precise mix design. Unlike site-cast concrete, precast manufacturing allows engineers and quality control teams to tightly regulate density, strength, and workability before production ever begins. Each mix is engineered to achieve a specific balance between weight reduction and structural performance.

At professional precast plants, trial batches are tested for compressive strength, density, air content, and moisture absorption. These tests ensure the final product consistently meets CSA and project-specific requirements. This level of control is especially critical for lightweight systems, where small variations can significantly impact performance.

- Target density verification for each batch

- Compressive strength testing at multiple ages

- Moisture and absorption control

- Documented quality assurance procedures

Forming, Casting & Curing

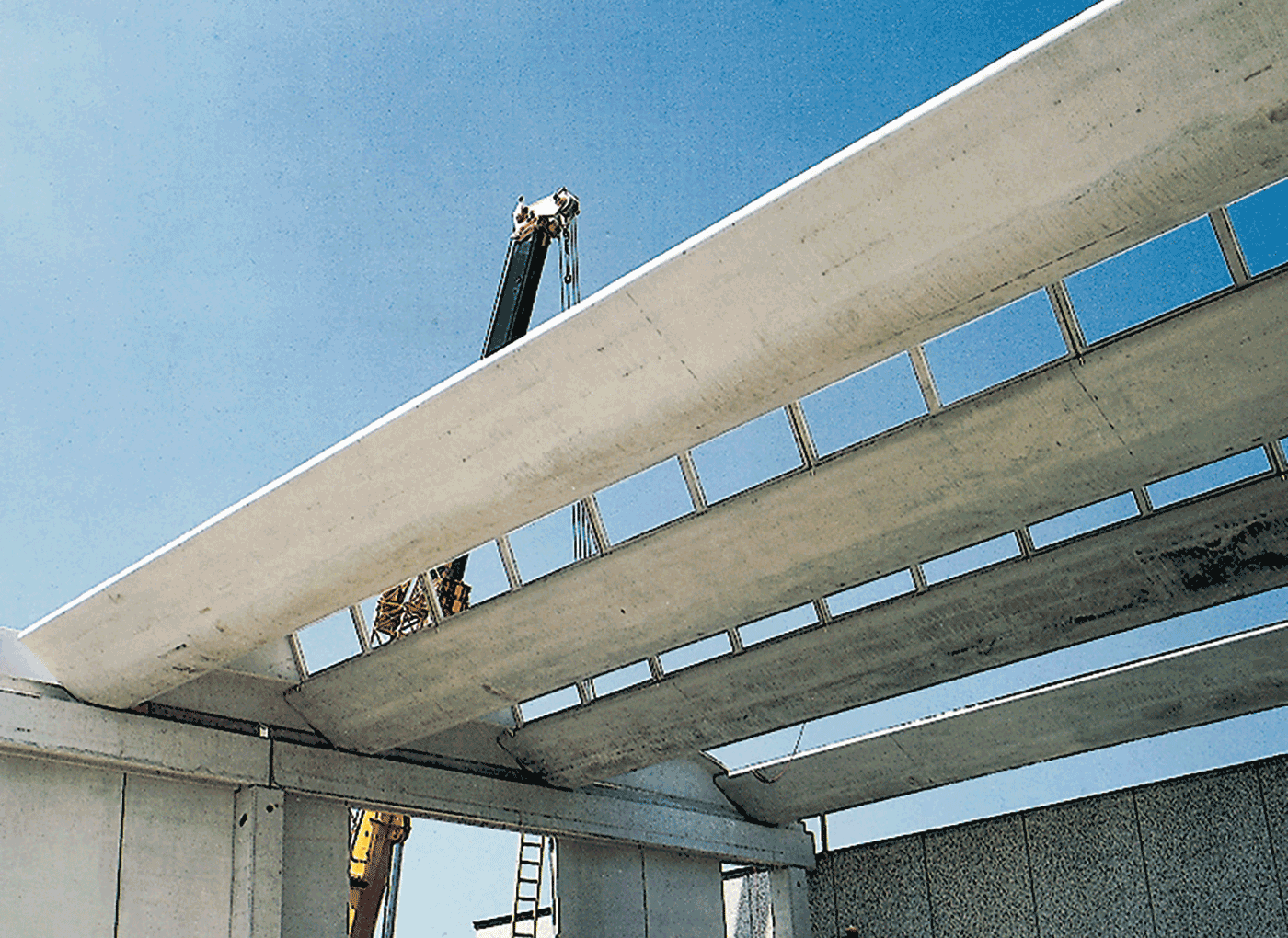

Once the mix is approved, concrete is placed into precision steel molds designed to maintain tight dimensional tolerances. Lightweight precast elements benefit greatly from factory casting, as consistent vibration, placement techniques, and finishing methods help prevent segregation of lightweight aggregates or EPS beads.

Curing methods vary depending on the system used. Steam curing is common for structural lightweight precast, accelerating strength gain and improving early-age performance. For EPS and AAC products, curing cycles are carefully calibrated to protect internal structure while achieving the required durability.

Reinforcement & Lifting Hardware

Despite being lighter, most lightweight precast elements are reinforced using conventional steel reinforcement, welded wire mesh, or prestressing strands. Embedded lifting anchors and connection hardware are engineered specifically for reduced panel weights, improving safety during handling and erection.

From an installation perspective, lighter elements often allow for smaller cranes, fewer picks, and faster erection cycles—reducing overall project risk and cost.

Plant-Controlled Advantages

Manufacturing lightweight precast concrete in a controlled plant environment delivers consistency that is nearly impossible to replicate on site. For Canadian projects, this translates into predictable schedules, reliable quality, and compliance with national building standards—regardless of weather conditions.

Efficient logistics and transport planning becomes far more manageable when lightweight precast systems are used.

Performance Benefits of Lightweight Precast Concrete

Structural Performance

One of the most common misconceptions about lightweight concrete is that reduced weight means reduced strength. In reality, many structural lightweight precast systems achieve compressive strengths comparable to traditional concrete while offering superior strength-to-weight ratios.

This makes lightweight precast particularly effective for mid-rise buildings, long-span floor systems, and structures where foundation loads must be minimized. In seismic design, reduced mass can also lower inertial forces acting on a building during an earthquake.

Thermal Efficiency

Thermal performance is a major driver behind the adoption of lightweight precast wall systems. The internal air structure of lightweight aggregates, EPS beads, or aerated concrete significantly reduces heat transfer compared to solid concrete.

For Canadian climates—where heating energy dominates annual building performance—this improved insulation can help projects meet or exceed energy code requirements while reducing long-term operating costs.

Speed of Installation

Because lightweight precast elements weigh less, they are faster to transport, easier to handle, and quicker to install. This often results in shorter crane times, fewer crew members required on site, and accelerated construction schedules.

For developers and general contractors, this speed advantage can translate directly into earlier occupancy and improved return on investment.

Lifecycle Cost Efficiency

While the upfront material cost of lightweight precast concrete may be similar to or slightly higher than conventional systems, the overall lifecycle cost is often lower. Savings are realized through reduced foundation requirements, lower transportation costs, faster installation, and improved energy performance over the life of the building.

Applications of Lightweight Precast Concrete

Residential Construction

In residential projects, lightweight precast concrete is commonly used for exterior wall panels, floor systems, and stair components. Its reduced weight makes it ideal for multi-family housing, townhomes, and modular residential construction.

- Exterior insulated wall panels

- Precast stair systems

- Lightweight floor and roof slabs

Commercial & Institutional Buildings

Schools, healthcare facilities, and office buildings benefit from lightweight precast’s combination of durability, fire resistance, and energy efficiency. Faster construction timelines are particularly valuable in institutional projects with strict schedules.

Industrial & Warehouse Facilities

For industrial buildings and warehouses, lightweight precast panels reduce structural steel requirements while maintaining durability and fire resistance. Large-format wall panels can be installed quickly, minimizing downtime and labor costs.

Modular & Remote Construction

Lightweight precast is especially valuable in modular construction and remote or northern projects across Canada. Reduced shipping weight lowers transportation costs and makes logistics more manageable in areas with limited infrastructure.

Lightweight Precast Concrete in Canadian Climate Conditions

Cold-Weather Durability

Canadian construction demands materials that can withstand repeated freeze-thaw cycles. Properly designed lightweight precast concrete incorporates air-entrainment and durable aggregates to maintain long-term performance even in harsh winter conditions.

Fire Resistance & Code Compliance

Lightweight precast concrete is non-combustible and can achieve excellent fire resistance ratings. Many systems meet or exceed National Building Code of Canada requirements, making them suitable for residential, commercial, and industrial use.

Sustainability & Carbon Reduction

By reducing material usage, transportation emissions, and operational energy demand, lightweight precast concrete supports sustainable building goals. When combined with supplementary cementitious materials, it can contribute to lower embodied carbon and green building certifications.

Design Considerations & Limitations

Load-Bearing Limits

While many lightweight precast systems are structural, they are not universally suitable for every application. Engineers must evaluate load requirements, spans, and connection details to determine whether lightweight or normal-weight precast is the better option.

Connection & Detailing

Connections between panels, floors, and structural frames must be carefully designed to accommodate reduced weight and different material properties. Proper detailing ensures long-term durability, thermal continuity, and structural performance.

Finish Options

Lightweight precast elements can be produced with a wide range of finishes, including smooth architectural surfaces, textured patterns, and applied coatings. This allows designers to achieve both functional and aesthetic goals without compromise.

Why Choose Omega Precast for Lightweight Precast Concrete

Design-Assist Expertise

Omega Precast works closely with architects, engineers, and contractors from the earliest design stages. This collaborative approach ensures lightweight precast elements are optimized for performance, constructability, and cost efficiency.

Advanced Manufacturing Capabilities

With modern equipment, precision molds, and experienced production teams, Omega Precast delivers consistent, high-quality lightweight precast components tailored to project-specific requirements across Canada.

Nationwide Project Support

From concept through installation, Omega Precast provides dependable service and logistics coordination, helping clients meet schedules and performance goals on projects of all sizes.

Frequently Asked Questions

Is lightweight precast concrete structural?

Yes. Many lightweight precast systems are engineered for structural use and can achieve compressive strengths comparable to traditional concrete.

How much lighter is lightweight precast concrete?

Depending on the system, lightweight precast concrete can be 20–40% lighter than normal-weight concrete.

Does lightweight concrete meet Canadian building codes?

When properly designed and manufactured, lightweight precast concrete complies with CSA standards and the National Building Code of Canada.

Is lightweight precast more expensive?

Initial costs may be similar, but lifecycle savings from faster construction and improved energy performance often make lightweight precast more cost-effective overall.

Conclusion & Call to Action

Lightweight precast concrete offers a smart balance of strength, efficiency, and sustainability for modern Canadian construction. By reducing structural loads, improving thermal performance, and accelerating installation, it delivers measurable value across residential, commercial, industrial, and modular projects.

If you’re considering lightweight precast concrete for your next project, partnering with an experienced manufacturer makes all the difference.

Contact Omega Precast today to discuss lightweight precast concrete solutions tailored to your project’s design, performance, and schedule requirements.