Over the past decade, the construction industry has been experiencing a major shift—one driven by speed, sustainability, digital transformation, and the pressure to build smarter, safer, and more efficiently. Innovations in precast concrete has rapidly evolved to meet these demands, becoming a leader in modern construction. From smart systems and embedded sensors to automation and next-generation materials, innovations in precast concrete are shaping what tomorrow’s buildings and infrastructure will look like.

As Canada continues to expand its urban centres, upgrade aging infrastructure, and deal with labour shortages, precast concrete is emerging as a crucial solution. In this article, we explore the newest technologies, trends, and smart systems redefining precast—and how companies like Omega Precast are leading this transformation across the country.

Innovations in precast concrete is becoming essential as the industry shifts toward smarter, faster, and more sustainable building solutions.

The Rise of Smart Precast Systems in Modern Construction

Smart technology is no longer just a trend—it is becoming a standard in large infrastructure and commercial developments. This shift is helping builders achieve higher precision, lower costs, and better long-term performance. Below are three of the most influential smart system innovations currently reshaping precast concrete.

Automation & Robotics in Precast Manufacturing

Automation and robotics have significantly improved manufacturing accuracy and reduced on-site labour requirements. Modern precast plants are now using automated systems for:

- Rebar bending and cage welding with robotic precision

- Automated mould preparation to speed up production cycles

- Robotic concrete placement and compaction for consistent density and finishes

- Laser-guided dimension checks to reduce quality-control errors

According to a study published by the International Concrete Federation, plants using automated mould systems see up to a 35% increase in production efficiency and a 25% reduction in material waste. For large-scale projects, these advantages compound into massive savings in time and labour.

This level of automation marks a major step forward in the ongoing innovations in precast concrete across modern manufacturing plants.

Automation also enhances worker safety. Instead of performing risky manual tasks, workers oversee machines, reducing exposure to repetitive strain and heavy-lifting hazards.

IoT Sensors Embedded in Precast Elements

One of the most exciting innovations in precast concrete is the integration of IoT (Internet of Things) sensors. These tiny devices are embedded inside precast components during production and offer real-time monitoring throughout the structure’s lifespan.

Common IoT sensor measurements include:

- Concrete moisture levels

- Temperature variations

- Crack development and movement

- Load and stress patterns

- Vibration and traffic impact (for bridges and pavements)

For municipalities and private developers, IoT-enabled precast offers a significant advantage: predictive maintenance. Instead of reacting to failures, building managers receive alerts long before issues become emergencies—saving money, preventing downtime, and extending the life of critical infrastructure. The integration of smart sensors represents one of the most impactful innovations in precast concrete, enabling real-time structural intelligence..

Smart monitoring is especially useful in Canada, where extreme cold and freeze-thaw cycles can deteriorate structures without early warning.

Smart Moulds & Digital Fabrication Tools

Digital fabrication is making it easier to produce highly customized precast designs. Smart moulds use programmable forms that automatically adjust dimensions, curves, and design features without needing a full manual rebuild.

These tools allow for:

- Faster prototyping for complex architectural elements

- Greater design flexibility for unique shapes

- Reduced labour time for mould adjustments

- Precision that meets modern engineering demands

This combination of speed and accuracy supports both mass-production projects and high-end architectural builds.

These digital tools continue to push innovations in precast concrete by allowing faster prototyping and greater customization.

Digital Transformation Technologies Shaping Precast Concrete

The future of precast is inseparable from digital transformation. Innovations in precast concrete increasingly depends on the seamless adoption of BIM, AI, and automated design environments. These technologies are not only improving how precast components are produced but also how they are designed, delivered, installed, and maintained throughout their lifecycle.

BIM Integration for Seamless Design & Production

Building Information Modeling (BIM) has become one of the most important tools in modern construction. In precast, BIM helps teams collaborate efficiently from concept to installation, avoiding delays and costly rework.

BIM helps by enabling:

- Clash detection between pipes, cables, and structural elements

- Shared 3D models for architects, engineers, and contractors

- Accurate quantity estimation to prevent material shortages

- Precise lifting and installation planning

A widely cited McKinsey report shows that full BIM integration can reduce project timelines by up to 10% and minimize construction waste by up to 20%. For precast, the benefits are even greater since components are fabricated off-site and require near-perfect coordination.

Digital Twins for Infrastructure Projects

Digital twins are virtual, real-time replicas of physical structures. Using data from sensors and BIM files, digital twins allow owners and engineers to simulate and monitor how a structure performs over time.

They are especially impactful in:

- Bridges (monitoring vibration, weight loads, crack development)

- Tunnels (tracking moisture, air flow, structural shifts)

- Highway systems (smart pavement monitoring)

- Large buildings (energy efficiency + structural health)

Digital twins increase lifespan predictions, reduce inspection costs, and support more sustainable decision-making.

AI-Driven Quality Control Systems

AI-powered quality control is quickly becoming a game changer in precast plants. Cameras and scanners equipped with machine learning can detect surface defects, air pockets, texture inconsistencies, and dimensional errors far faster than the human eye.

AI improves productivity through:

- Automated defect recognition on fresh and cured concrete

- Real-time reporting for immediate corrections

- Predictive analytics that identify recurring issues

- Consistent quality control across large production volumes

AI-powered monitoring represents a significant innovations in precast concrete, improving accuracy and reducing production waste. This reduces rejected batches, speeds up output, and increases overall reliability—essential for major infrastructure projects where precision and durability matter most.

Future Materials Transforming Precast Concrete

Material science is evolving rapidly, offering groundbreaking innovations that enhance strength, durability, sustainability, and efficiency. Below are the three most important emerging materials shaping the next decade of precast concrete manufacturing.

Ultra-High-Performance Concrete (UHPC)

Ultra-High-Performance Concrete is one of the most celebrated innovations in modern material science. UHPC provides compressive strength levels exceeding 150 MPa, more than 10 times stronger than typical structural concrete.

UHPC benefits include:

- Longer spans with thinner sections

- Superior durability and abrasion resistance

- Minimal maintenance requirements

- Extended service life for bridges and infrastructure

In Canada, UHPC is increasingly used for bridge girder connections, architectural façades, and high-performance structural elements in harsh climates.

Carbon-Cured & Carbon-Negative Precast

Carbon-curing technology is transforming sustainability efforts across North America. Instead of traditional steam curing, CO₂ is injected into the concrete during curing, where it becomes permanently mineralized.

Benefits of carbon-cured concrete include:

- Up to 30% reduction in carbon footprint

- Stronger early-age strength

- Faster curing and production cycles

- Compliance with green building standards

This technology is aligned with Canada’s 2030 Emissions Reduction Plan and is being rapidly adopted by progressive precast manufacturers.

Self-Healing Concrete Innovations

Self-healing concrete technologies are showing immense promise for long-term durability. These systems repair cracks automatically using embedded bacteria or polymer microcapsules.

Types of self-healing systems:

- Bacteria-based healing that activates when exposed to moisture

- Microcapsule polymers that release sealant when cracks form

- Shape-memory materials that expand to close gaps

This reduces maintenance expenses dramatically and is ideal for tunnels, bridges, marine structures, and remote installations where repairs are difficult.

Material science is one of the fastest areas for innovations in precast concrete, driving major improvements in strength and durability.

Sustainability Trends in Precast Concrete

As environmental performance becomes a top priority for municipalities, developers, and infrastructure planners, precast concrete is experiencing a significant shift toward greener, more efficient manufacturing practices. Modern sustainability innovations in precast concrete are not only reducing emissions but also extending the life cycle of structures and lowering long-term costs.

Circular Economy & Recycled Materials

One of the major sustainability advancements in precast is the adoption of circular economy principles. Manufacturers are increasingly incorporating recycled materials into their products without compromising performance or durability.

- Recycled aggregates from construction waste

- Recycled steel reinforcement from industrial scrap

- Reclaimed water used in batching and mixing

This approach conserves natural resources, reduces landfill burden, and aligns with federal sustainability targets in Canada. Sustainability requirements across Canada continue to accelerate innovations in precast concrete, particularly in low-carbon manufacturing.

Energy-Efficient Precast Plants

Advanced precast facilities are now integrating energy-saving systems to reduce overall carbon footprints. These improvements enhance both sustainability and production efficiency.

- Closed-loop water recycling systems to reduce water consumption

- Solar-powered curing chambers that reduce the need for fuel heating

- Optimized batching technologies that minimize raw material waste

These measures contribute to lower operating costs and enhanced environmental certifications.

.png)

Low-Carbon Manufacturing & Green Certifications

With growing demand for eco-friendly construction, many Canadian builders are turning to precast concrete that meets LEED, BREEAM, and other green building requirements.

Low-carbon innovations include:

- Carbon-neutral binders

- Low-energy curing technologies

- Environmental Product Declarations (EPDs) for full transparency

These practices enhance trust, improve bidding competitiveness, and support Canada’s nationwide sustainability goals.

Smart Infrastructure & Precast Concrete in Smart Cities

As smart cities grow across Canada and worldwide, precast concrete has become a foundational element in developing intelligent infrastructure. From monitoring traffic loads to optimizing public utilities, smart precast products are enabling cities to operate more efficiently.

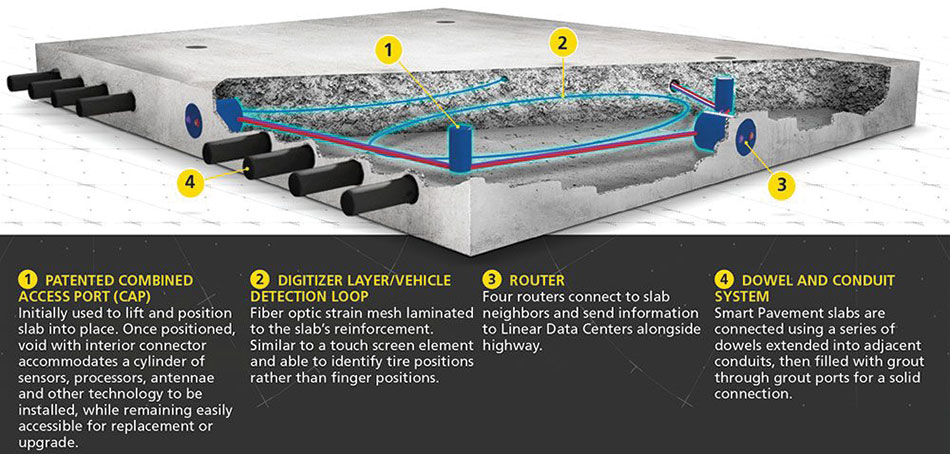

Smart Pavements & Traffic Systems

Smart pavements built with precast components embed sensors that track performance in real-time. These systems help municipalities detect issues early and make data-driven decisions.

- Vibration and traffic volume monitoring

- Temperature and freeze-thaw data

- Impact load and structural shifts

By using these technologies, cities can reduce maintenance costs and extend roadway lifespans dramatically. As cities adopt intelligent infrastructure, innovations in precast concrete becomes central to building roads and utilities that can self-monitor and adapt.

Modular Precast Systems for Smart Urban Development

Modular precast construction plays a crucial role in building scalable, efficient smart cities. It offers speed, consistency, and adaptability—perfect for rapid urban growth.

Common modular precast applications include:

- Rapid-build housing

- Transit stations and platforms

- Utility and electrical vaults

- Commercial modular units

These solutions help cities meet evolving demands with minimal disruption and reduced environmental impact.

Case Studies: Global Cities Using Smart Precast

Worldwide, several cities have embraced innovative precast systems:

- Singapore → Precast panels embedded with smart sensors for structural monitoring.

- Dubai → Modular precast systems used for rapid urban expansion.

- Toronto → Smart pavement testing projects aimed at improving winter performance.

These examples demonstrate how precast is shaping the future of global urban development.

How These Innovations in Precast Concrete Improve Project Outcomes

The adoption of smart systems, new materials, and digital tools helps project owners, engineers, and contractors achieve better outcomes across every phase of construction.

Faster Construction Timelines

Off-site precast production significantly reduces delays caused by weather, labour shortages, and onsite complexities. This is particularly valuable for Canadian projects with short building seasons.

Reduced Long-Term Maintenance Costs

IoT-enabled precast and self-healing materials ensure long-term performance with minimal maintenance. Predictive monitoring allows project owners to address issues early—before they become serious problems.

Improved Worker Safety & Labour Optimization

Automation reduces manual risk exposure, while modular precast construction cuts the need for prolonged onsite work. This results in safer job sites and better workforce allocation.

What Future Trends Will Shape Precast in the Next 10 Years?

The future of precast concrete is filled with exciting advancements driven by technology, sustainability, and demand for smarter infrastructure. Key trends to watch include:

3D Printing + Precast Hybrid Systems

Hybrid components created by combining the flexibility of 3D printing with the durability of precast will revolutionize custom architecture and infrastructure.

Smart Transportation Infrastructure

Autonomous vehicle systems, EV charging pavements, and sensor-integrated transit structures will rely heavily on advanced precast technologies.

Fully AI-Automated Precast Facilities

Future plants may run almost entirely on artificial intelligence—optimizing mixing, casting, curing, tracking, and logistics.

Rapid Disaster-Resistant Structures

Earthquake-resistant, fire-resistant, and hurricane-resistant precast modules will become critical as climate-related events increase worldwide.

Why Innovations in Precast Concrete Matters for Canadian Construction

Canada’s unique construction environment makes precast particularly valuable. Weather conditions, workforce shortages, rugged terrains, and remote project locations demand efficient, durable, and reliable building solutions.

Innovative precast helps Canada overcome:

- Short construction seasons due to extreme winters

- High labour costs and skilled worker shortages

- Transportation challenges in remote industrial sites

- Growing infrastructure needs in fast-developing cities

With innovations in precast concrete at the forefront, precast becomes the most practical and future-proof choice.

Why Choose Omega Precast for Modern Precast Solutions?

At Omega Precast, we continually invest in advanced technologies, sustainable practices, and smart manufacturing systems to deliver the highest-quality precast concrete across Canada. Omega Precast is committed to leading innovations in precast concrete through advanced technologies and future-ready solutions.

Advanced Manufacturing Capabilities

We use modern equipment, automated production systems, and high-precision digital tools to ensure accuracy and fast delivery.

High-Precision Quality Control

Our rigorous QA/QC processes—including digital inspections—guarantee consistent performance and reliability in every component.

Sustainable & Smart Precast Options

We offer carbon-cured concrete, recycled material integration, and IoT-enabled precast solutions for future-ready structures.

Fast Delivery Anywhere in Canada

Our nationwide service ensures timely delivery for projects of all sizes—from residential to industrial and large municipal infrastructure.

Ready to build smarter, faster, and more sustainably? Contact Omega Precast today for a custom quote and expert project support.

Conclusion: The Future Is Smart, Sustainable & Precast

The innovations in precast concrete are transforming the construction industry. From IoT monitoring and digital twins to carbon-cured materials and smart pavements, precast is set to play a leading role in building the next generation of infrastructure—especially in Canada.

By embracing these advancements now, developers, engineers, and municipalities can future-proof their projects and achieve better performance, lower costs, and longer-lasting results.

Frequently Asked Questions (FAQ)

What is smart precast concrete?

Smart precast concrete includes components enhanced with IoT sensors, digital tracking, automation, and intelligent monitoring systems that improve performance and durability.

How do IoT sensors work in precast structures?

IoT sensors embedded inside the concrete collect real-time data on temperature, moisture, vibration, and structural integrity, helping owners predict issues and schedule maintenance efficiently.

Is smart precast concrete more expensive?

While initial costs may be slightly higher, long-term savings from lower maintenance, reduced repairs, and extended lifespan make it a cost-effective choice.

What is the future of precast in Canada?

Canada is rapidly adopting smart, sustainable precast technologies to support urban growth, infrastructure modernization, and eco-friendly building practices.

What projects benefit most from modern precast systems?

Smart precast is ideal for bridges, highways, modular buildings, utility structures, high-performance façades, and other major infrastructure projects.