Sustainability precast concrete is transforming modern construction across Canada. As environmental priorities redefine building standards, developers and architects are asking: How eco-friendly is precast concrete really? This comprehensive analysis reveals why sustainability precast concrete solutions are becoming the preferred choice for green building projects.

While concrete has long been criticized for its carbon footprint, modern precast technologies are reshaping the narrative. Factory-controlled production, reduced waste, energy-efficient curing, and end-of-life recyclability are just a few reasons precast concrete is increasingly recognized as a more sustainable building option—especially when manufactured by experienced providers like Omega Precast. According to the National Precast Concrete Association (NPCA), factory production can reduce material waste by up to 20–30% compared to on-site methods. A key advantage of sustainability precast concrete is its optimized production process, which not only minimizes waste but also significantly lowers energy consumption and carbon emissions through precise control and efficient curing systems.

In this in-depth sustainability analysis, we break down the environmental impact of precast concrete, compare it with traditional cast-in-place methods, and explore how it supports greener building initiatives across Canada—building on a broader comparison of the differences between precast concrete and cast-in-place construction methods.

What Makes Sustainability Precast Concrete an Eco-Friendly Choice?

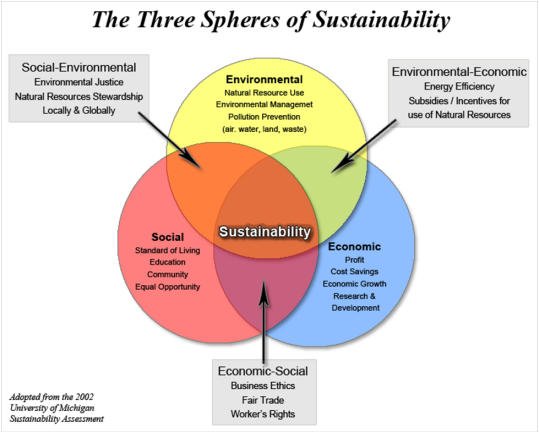

Before evaluating precast concrete specifically, it’s important to understand what qualifies a construction material as “eco-friendly.” In sustainability frameworks—including LEED, CaGBC, and Green Globes—materials are assessed across several environmental performance indicators.

Key Sustainability Criteria

For a construction material to be considered environmentally responsible, it should meet at least several of the following criteria:

- Low Embodied Carbon: Reduced greenhouse gas emissions across extraction, production, transportation, installation, and end-of-life stages.

- Efficient Production Processes: Minimal waste generation, energy-efficient manufacturing, and optimized resource use.

- Recyclability & Circularity: Ability to reuse materials or components, reducing landfill impact.

- Durability & Longevity: Strong resistance to weather, corrosion, and time—leading to lower replacement frequency.

- Water & Energy Conservation: Production methods that consume fewer natural resources.

These principles form the backbone of modern sustainable engineering. As we’ll see, precast concrete performs strongly in many of these categories.

How Precast Aligns with Eco-Friendly Evaluation Frameworks

Many environmental certification programs reward materials that minimize waste, reduce energy use, and improve long-term performance. Precast concrete aligns with these goals by offering:

- Controlled production for consistent, energy-efficient curing

- Reduced jobsite emissions and minimized disruption

- Extended structural lifespan compared to conventional alternatives

- High recyclability at end-of-life

These characteristics place precast concrete firmly within the sustainability criteria defined by global green building programs.

Sustainability Precast Concrete Overview: How It Works & Why It Matters

Precast concrete stands apart from many other building materials due to its unique manufacturing process. Instead of mixing and pouring concrete on-site, precast components are produced inside a controlled factory environment where variables like temperature, curing time, and material ratios can be precisely managed.

But how does this translate into real environmental benefits? Let’s break it down.

Factory-Controlled Production & Its Environmental Benefits

Unlike cast-in-place concrete, precast components are not subject to on-site variability, weather delays, or inconsistent mixing. This leads to significant sustainability advantages:

- Reduced waste: Factories optimize material use with precise measurements and batching systems.

- Lower water consumption: Recycled water and efficient curing processes reduce overall usage.

- Improved quality control: Higher strength materials often result in longer-lasting structures, which reduces life cycle emissions.

According to the National Precast Concrete Association (NPCA), factory production can reduce material waste by up to 20–30% compared to on-site methods.

Reduced Material Waste in Precast Production

Because precast is manufactured using reusable steel moulds, material optimization is significantly higher. A typical formwork can be reused hundreds or even thousands of times, which reduces:

- Excess concrete

- Packaging waste

- Landfill contributions

- Cost and environmental resource consumption

In contrast, cast-in-place formwork—often made of wood or low-durability materials—has a far shorter lifespan and contributes to substantial construction waste.

Energy Efficiency During Manufacturing

Precast plants typically use highly efficient curing systems and machinery designed to maximize energy performance. For example:

- Automated batching systems reduce mixing energy waste.

- Optimized curing chambers maintain precise temperatures, lowering fuel consumption.

- Centralized operations reduce the need for multiple pieces of site equipment.

This level of efficiency is difficult—if not impossible—to achieve in outdoor or temporary site setups.

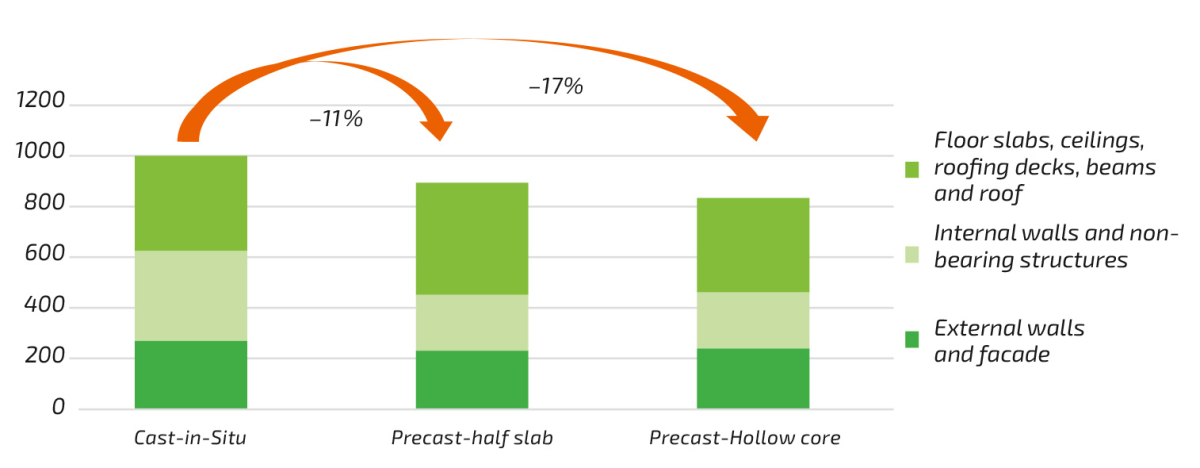

Precast Concrete vs Cast-In-Place: Environmental Comparison

One of the best ways to understand the eco-friendly advantages of precast is by examining how it compares to traditional cast-in-place concrete, which is still widely used in many projects across Canada.

Carbon Footprint Analysis

Both precast and cast-in-place concrete rely on cement, which is the main contributor to concrete’s carbon footprint. However, the way the materials are handled differs greatly.

Precast concrete generally has a lower overall carbon footprint due to factors such as:

- Reduced on-site machinery: Less equipment = fewer emissions.

- Optimized curing: Energy-efficient curing lowers embodied carbon.

- Lower transportation waste: Bulk production consolidates vehicle usage.

Waste Generation Comparison

When evaluating environmental impact, waste reduction is crucial. Here’s how the two methods compare:

- Precast: Minimal waste due to precise moulds and controlled production.

- Cast-in-place: Higher potential for spills, batching errors, and formwork waste.

Life Cycle Assessment (LCA)

Studies show that the majority of concrete’s environmental impact occurs during production. However, its lifespan has a major influence on overall sustainability.

Precast concrete often lasts longer due to stronger curing conditions and higher-quality manufacturing. This means:

- Fewer repairs

- Lower long-term emissions

- Smaller environmental footprint across decades

Environmental Comparison Table: Precast vs Cast-In-Place

| Factor | Precast Concrete | Cast-In-Place Concrete |

|---|---|---|

| Material Waste | Low (controlled production) | High (on-site variability) |

| Carbon Footprint | Lower overall | Higher due to on-site emissions |

| Durability | High | Moderate |

| Recyclability | High | Moderate |

| Energy Efficiency | High | Low to Moderate |

How Sustainability Precast Concrete Lowers Carbon Emissions

Concrete will never be a zero-carbon material—but precast approaches significantly reduce the total environmental impact by optimizing each part of the production process. A key advantage of sustainability precast concrete is its optimized production process, which ensures materials are mixed to exact proportions in a controlled factory setting. This leads to:

- Improved thermal performance

- Reduced cement waste

- Higher strength with fewer materials

Optimized Production Processes

In a controlled plant environment, materials are mixed to exact proportions. This ensures:

- Reduced cement waste

- Higher strength with fewer materials

- Improved thermal performance

Better material performance leads to structures that last longer and require fewer replacements over time—a major environmental benefit.

Lower On-Site Emissions

Installing precast components involves significantly fewer on-site activities than cast-in-place installation. This reduces:

- Diesel emissions from heavy equipment

- Dust and particulate pollution

- Noise pollution impacting nearby communities

Transportation Efficiency

While precast components are large, transportation is often more efficient because materials are shipped in bulk to the manufacturing plant, not to multiple job sites. Meanwhile, onsite mixing vehicles and equipment are minimized.

Material Efficiency & Waste Reduction in Precast Plants

One of the strongest sustainability advantages of precast concrete lies in its material efficiency. Because components are produced in a controlled facility, producers can carefully monitor material usage and reduce wastage that typically occurs on busy construction sites.

Reusable Mould Systems

Precast formwork can be reused hundreds or even thousands of times, dramatically reducing waste generated by single-use or limited-use formwork in cast-in-place projects. This system not only conserves raw materials but also lowers production costs—benefits that ultimately support more eco-friendly building practices.

- Steel moulds maintain precision and durability across multiple production cycles.

- Minimal formwork disposal reduces landfill contribution.

- Less timber dependency aligns with forest conservation goals.

Recycling Concrete Aggregates

Many precast plants, including sustainable producers across Canada, actively recycle leftover concrete. This involves crushing cured material into recycled aggregate, which can be reused in new mixes or repurposed for road base and other applications.

Recycling aggregates helps:

- Reduce demand for virgin raw materials

- Lower transportation emissions from quarrying

- Support circular construction economy principles

Less Packaging Waste Compared to On-Site Builds

On-site construction often involves pallets, bags, plastic wraps, and packaging that accumulates quickly. Precast production significantly reduces this waste because materials are stored in bulk, handled with machinery, and controlled within a single facility.

This streamlined approach cuts down overall project waste and helps companies minimize environmental impact from start to finish.

Durability & Longevity: The Core of Sustainability Precast Concrete

Durability is a core pillar of sustainable construction. A longer-lasting structure reduces repair cycles, material replacement, and the environmental cost of renovations or rebuilds. Precast concrete excels in this area.

Longer Lifespan = Smaller Environmental Footprint

Because precast concrete cures under carefully controlled conditions, the final product often achieves higher strength and density than site-poured alternatives. This improved performance leads to a significantly extended structural lifespan.

For example, precast components commonly offer:

- High compressive strength with reduced microcracking

- Superior moisture resistance in harsh climates

- Enhanced freeze-thaw durability—especially important in Canadian weather

Lower Maintenance Needs Reduce Environmental Burden

Lower maintenance translates directly into environmental savings. Each avoided repair reduces emissions from materials manufacturing, transportation, and construction equipment.

In many cases, precast structures outperform traditional concrete in:

- Surface longevity

- Structural stability

- Resistance to spalling, corrosion, and chemical exposure

Superior Resistance to Weather & Environmental Stressors

Precast’s durability makes it ideal for regions with extreme conditions such as heavy snow, high winds, or temperature fluctuations. The more resistant a material is to environmental stress, the more sustainable it becomes over its lifespan.

Recyclability & End-of-Life Environmental Performance

Sustainability doesn’t end when a structure reaches the end of its service life. A truly eco-friendly material supports recycling or repurposing—and precast concrete performs strongly in this stage as well.

Can Precast Concrete Be Recycled?

Yes. Precast concrete is fully recyclable. Once dismantled, components can be crushed into recycled aggregate, which is then used for new concrete products, landscaping fill, or road base.

- Steel reinforcement inside precast can be recovered and recycled.

- Aggregates can be repurposed for new construction applications.

- Crushed precast is an excellent low-carbon alternative to virgin materials.

Life Cycle Extension Through Repurposing

In some cases, precast elements such as barriers, panels, or blocks can be reused without recycling. This extends the life cycle of the material even further, significantly reducing demand for new production.

Precast Concrete in Green Building Certifications

Because precast concrete supports waste reduction, durability, and efficient material usage, it contributes positively to many green certification systems.

LEED Credits

In LEED (Leadership in Energy and Environmental Design), precast concrete can contribute to multiple credit categories, including:

- Materials & Resources (MR): recycled content, regional materials, construction waste reduction

- Energy & Atmosphere (EA): improved building energy performance

- Innovation (IN): unique sustainable precast production initiatives

Zero-Carbon and Net-Zero Building Compatibility

With its long lifespan, excellent thermal performance, and potential integration into insulated wall systems, precast plays a strong role in reducing operational energy for buildings aiming for net-zero status.

Canadian Sustainability Programs (CaGBC, Green Globes)

Precast aligns with Canadian environmental frameworks by supporting:

- Regional material sourcing

- Reduced construction waste

- Improved building envelope performance

Common Myths About Precast Concrete & Sustainability

“Concrete Is Always Harmful to the Environment”

While concrete does have environmental impacts, precast production significantly reduces many of the industry’s biggest challenges—especially waste and inefficiency.

“Precast Uses More Cement”

In reality, precast often uses less cement overall because stronger mixes allow for thinner sections and fewer repairs over time.

“Transportation Emissions Make Precast Worse”

This is only true when precast must be shipped extremely long distances. In most cases—especially with local manufacturers like Omega Precast—the transportation footprint is lower than the cumulative emissions from multiple on-site batches and equipment.

When Precast Is Not the Most Eco-Friendly Choice

Long-Distance Transportation Challenges

If precast must be shipped several hundred kilometers, transportation emissions can outweigh production efficiencies.

Projects Requiring Unique One-Off Formwork

Highly customized components that require non-reusable moulds reduce the environmental benefits.

Improper Disposal or Lack of Recycling Programs

To achieve its full sustainability value, precast must be properly recycled at end-of-life. Regions without good recycling infrastructure may not realize all benefits.

Real-World Case Studies

Sustainable Precast Bridges

Many Canadian bridges have adopted precast girders due to their durability, reduced waste, and faster installation windows that minimize environmental disturbance.

Precast in Energy-Efficient Residential Builds

Homeowners and developers are increasingly using precast insulated wall panels to reduce heating and cooling costs—critical in Canada’s cold climate zones.

Multi-Storey Buildings Using Precast for LEED Points

Commercial buildings using precast systems benefit from improved air tightness, structural longevity, and easier compliance with LEED’s Materials & Resources credits.

How Omega Precast Supports Sustainable Construction in Canada

Modern Low-Waste Manufacturing Equipment

Omega Precast uses advanced batching and curing systems designed to reduce waste and maximize energy efficiency.

Optimized Material Usage

Through precise mix control and reusable moulds, we ensure minimal material waste across all production cycles.

Local Delivery Reduces Transportation Emissions

By serving regions across Canada, we reduce long-haul transportation emissions and support environmentally responsible delivery practices.

Commitment to Recycling & Eco-Friendly Practices

Our facility integrates recycled aggregates, reclaims materials whenever possible, and actively supports a circular construction economy.

Summary — Is Precast Concrete Truly Eco-Friendly?

After analyzing its entire life cycle—from raw materials to end-of-life—precast concrete emerges as a highly sustainable choice for many construction projects. With reduced waste, lower on-site emissions, impressive durability, and strong recyclability, precast offers clear environmental advantages over traditional cast-in-place concrete.

While it is not perfect for every situation, precast is one of the most eco-friendly concrete solutions available today—especially when sourced from responsible manufacturers using modern, low-waste production methods.

FAQ

Is precast concrete environmentally friendly?

Yes. Precast concrete reduces waste, improves material efficiency, and offers long-term durability, making it an eco-friendly building solution.

What is the carbon footprint of precast vs cast-in-place?

Precast generally has a lower overall carbon footprint due to optimized curing, reduced equipment use, and minimized on-site emissions.

Can precast concrete be recycled?

Absolutely. Precast concrete can be crushed into recycled aggregate, and steel reinforcement can be reused.

Does precast help achieve LEED certification?

Yes, precast contributes to LEED credits related to materials, waste reduction, and energy performance.

Is precast better for large or small projects?

Precast is suitable for both. Its eco-friendly advantages apply to residential, commercial, industrial, and infrastructure builds.

Ready to Build More Sustainably?

Omega Precast is committed to helping contractors, developers, and homeowners across Canada build greener, more efficient, and more durable structures. If you’re exploring sustainable precast solutions for your project, we’re here to help.

Contact Omega Precast today for a fast quote and expert guidance on eco-friendly precast products.